1.What is laser marking?

Laser marking is a process that uses laser technology to mark the surface of various materials. Through the focus of a high-energy laser beam, laser marking can form a permanent pattern, text or barcode on the surface of the material. Laser marking has the advantages of high precision, high speed and non-contact processing, and is widely used in manufacturing, electronics, medical, automotive and other industries. Compared with traditional marking methods, laser marking not only reduces material loss, but also ensures the durability and clarity of the mark.

The following content can help you buy your first fiber laser marking machine and make suggestions.

2.Working principle of fiber laser marking machine

Fiber laser marking machines mainly rely on fiber lasers to generate high-energy laser beams. Its working principle is as follows:

-

Laser generation: Fiber laser generates laser by exciting rare earth elements (such as erbium and ytterbium) in optical fiber.

-

Laser focusing: The laser beam is focused by the lens to form a high-energy density spot.

-

Material marking: The focused laser beam irradiates the surface of the material, instantly heating up, causing physical or chemical changes on the surface of the material, thus forming a mark.

-

Cooling and protection: The laser marking process is contactless and will not cause mechanical damage to the material.

3.Types of laser marking

Laser marking includes several types, such as engraving, coloring, and annealing. The choice of laser marking method depends on the material to be marked, its quality, and application requirements. The following are some common types of laser marking.

-

Laser engraving

Laser engraving is the use of a laser beam to remove material from the surface of a material to create a recessed permanent mark. This marking method is used to engrave two-dimensional codes, scales, and other applications that require deep marking.

The most intuitive difference between laser engraving and marking is that laser engraving can produce deep engraved marks.

Laser engraving involves removing material from the surface to form a deep mark. The laser beam is applied to the surface of the material, causing it to heat up rapidly, the surface material reaches the melting point, and then evaporates.

-

Laser etching

Similar to laser engraving, laser etching removes surface material, but leaves a lighter mark. It is often used to leave high-contrast and precise marks on metals, glass, ceramics, and coated materials.

-

Laser annealing

Laser annealing uses laser heating to change the surface color or oxidation of the material. This process does not remove material. It is mainly used to mark metals, especially stainless steel and titanium. The working principle of laser annealing is to apply a small amount of heat to the surface of an object through a laser beam. This causes a thermochemical reaction.

The most common color of annealing marking is black, and its main advantages include fast processing speed, small material deformation, and high processing accuracy. It has been applied in many fields such as aerospace, automobile and electronic equipment manufacturing.

-

Laser ablation

Laser ablation is the removal of the surface layer of the material by evaporation, and is often used for high-precision fine marking of materials such as ceramics, plastics and organics.

-

Laser foaming

Laser foaming is a plastic marking method in which the laser heats the plastic surface, resulting in controlled expansion. Laser foaming forms a raised foam-like mark on the plastic surface. The mark produced by laser foaming will be slightly lighter than the color of the original material, so it is more suitable for marking dark plastics.

-

Laser carbonization

Laser carbonization is suitable for materials containing carbon molecules, including organic materials, wood, leather or carbon steel. The high-energy laser beam causes the carbon molecules to migrate to the surface of the material and combine with the material molecules to form a dark mark.

-

Laser coloring

The laser beam causes the color change of some materials by changing the surface structure of the material, resulting in bright and colorful marks. The main principle of laser coloring is to induce an oxidation reaction on the surface of the material by adjusting the speed and power of the laser, thereby producing a colored mark.

4.Types of laser marking machines

There are mainly the following types of laser marking machines:

-

Fiber laser marking machine: suitable for metals and some plastics, with high efficiency and marking quality.

-

CO2 laser marking machine: suitable for non-metallic materials such as wood, paper and leather, often used for packaging and identification.

-

Solid laser marking machine: suitable for small precision marking, usually used for electronic components and jewelry marking.

-

UV laser marking machine: suitable for applications with high precision requirements, especially in the pharmaceutical and food industries.

5.Factors to consider when buying a fiber laser marking machine

-

Laser power

Choose the right power: Depending on your marking material and needs, the power is usually between 20W and 100W. High power is suitable for large-area marking and high-speed production, while low power is suitable for fine marking.

-

Applicable materials

Compatibility: Make sure the laser marking machine can handle the materials you commonly use, including metals (such as stainless steel, aluminum, copper), plastics, ceramics, etc. The material compatibility of different models varies.

-

Marking speed and efficiency

Production efficiency: Choose a device that can provide high marking speed to meet the needs of the production line. The faster the speed, the higher the efficiency.

-

Marking quality

Clarity and fineness: Check the marking quality of the equipment to ensure that the required text clarity and details can be achieved. This is crucial for the appearance and identification of the product.

-

Safety performance

Laser beams are very dangerous, and the machine needs to be equipped with various protection measures to ensure the safety of the operator. The most common features include tilting the machine to stop the laser beam, housing protection, emergency stop button, and many other safety features.

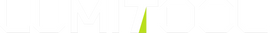

6.Best Fiber Laser Marker: LumiTool F20

LumiTool F20 is an award-winning fiber laser marker with the following features:

-

High efficiency: It can complete high-quality marking in a short time and improve production efficiency.

-

Versatile: It supports marking of a variety of materials, including metal, plastic, ceramic, etc.

-

User-friendly interface: It is equipped with an intuitive and easy-to-use software interface, which is simple to operate and suitable for novices and professionals.

-

Stability: It adopts advanced fiber laser technology to ensure long-term stable operation.

7.Application of Fiber Laser Marking Machines

Fiber laser marking machines are widely used in various industries. Some common applications include:

- Product identification: Fiber laser marking machines can mark basic information such as serial numbers, part numbers, barcodes, QR codes, logos, etc. on various metal materials such as iron, aluminum, brass, etc.

- Automotive industry: Fiber laser marking machines can be used in the automotive industry to mark parts, including engine parts, chassis, gears, bearings, and electrical connectors. It provides high-contrast permanent marking that can withstand harsh environments and ensure traceability.

- Electronic products: Fiber laser marking machines can mark electronic components, circuit boards, connectors, and cables. They can perform precise marking without damaging sensitive electronic components.

- Medical devices: Fiber laser marking machines can be used to mark surgical instruments, implants, medical devices, and pharmaceutical packaging.

- Aerospace: In the aerospace and defense fields, fiber laser marking machines can mark aircraft parts, identification labels, serial numbers, and part numbers. Laser marking provides permanent marking that can withstand extreme conditions and ensure the integrity of critical components.

- Jewelry and Luxury Goods: Fiber laser marking machines offer precise and intricate marking capabilities for custom jewelry and luxury goods.

- Packaging and Labeling: Fiber laser marking machines can mark packaging materials such as cardboard, paper, plastic, and flexible packaging. This includes marking batch numbers, expiration dates, product information, and logos for brand identification.

- Art and Personalization: Fiber laser marking machines can also be used for artistic and personalization purposes. They can engrave designs, patterns, and artwork on a variety of materials, enabling customized gifts, awards, signs, and decorations.

8.Conclusion

Fiber laser marking machines can mark a variety of metal materials, leaving a permanent mark with clear contrast. You can set the machine's parameters to achieve high-quality marking.

Here, I share with you the LumiTool F20, a 20w fiber laser marking machine that will give you great value for money in terms of functionality, marking speed, and quality.