A laser marking machine works by directing a highly focused laser beam onto a material, which causes the surface of the material to change color or texture. This change is known as ablation, and it can be used to create a permanent mark or engraving on the surface of the material.

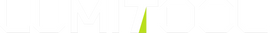

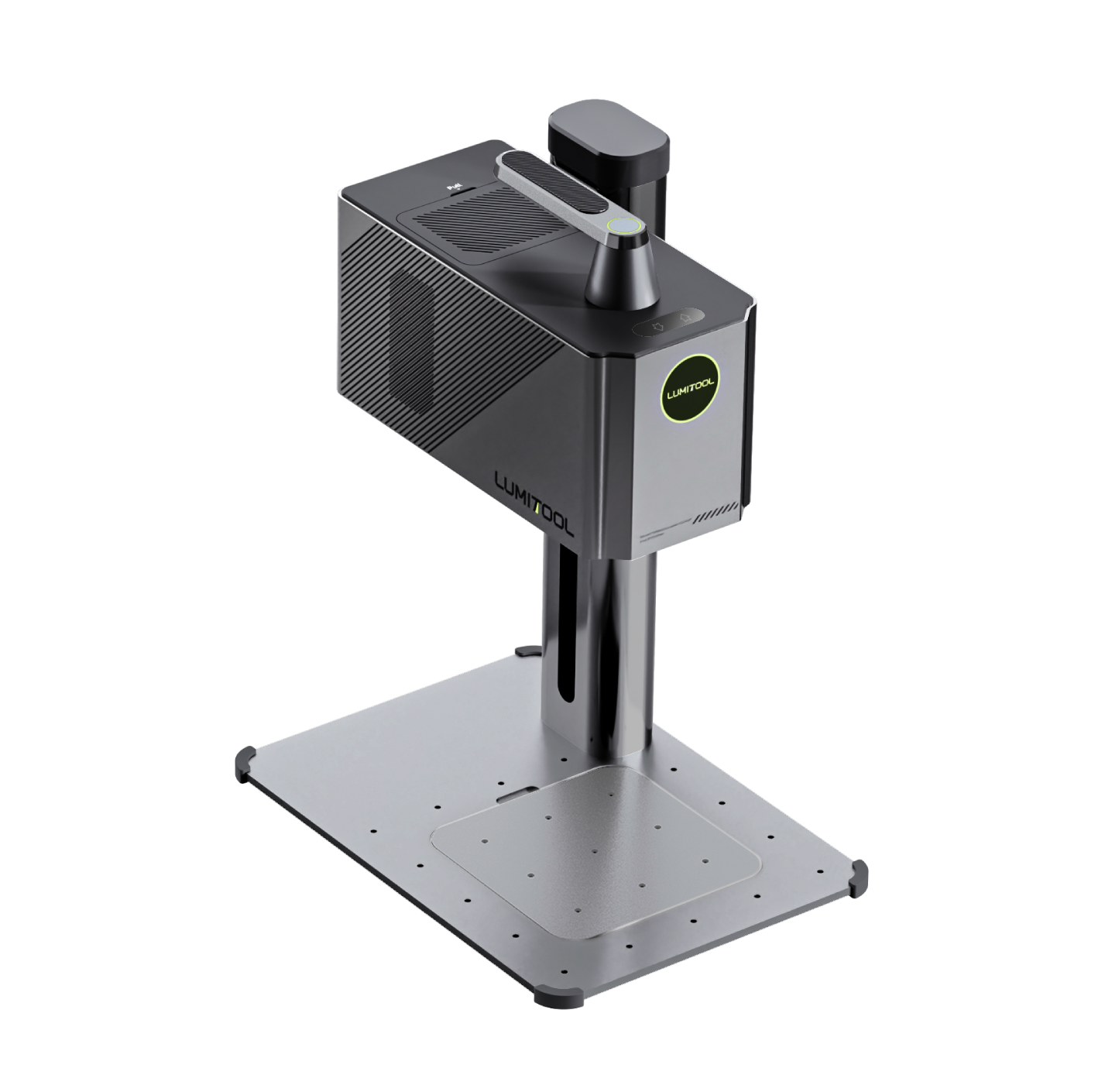

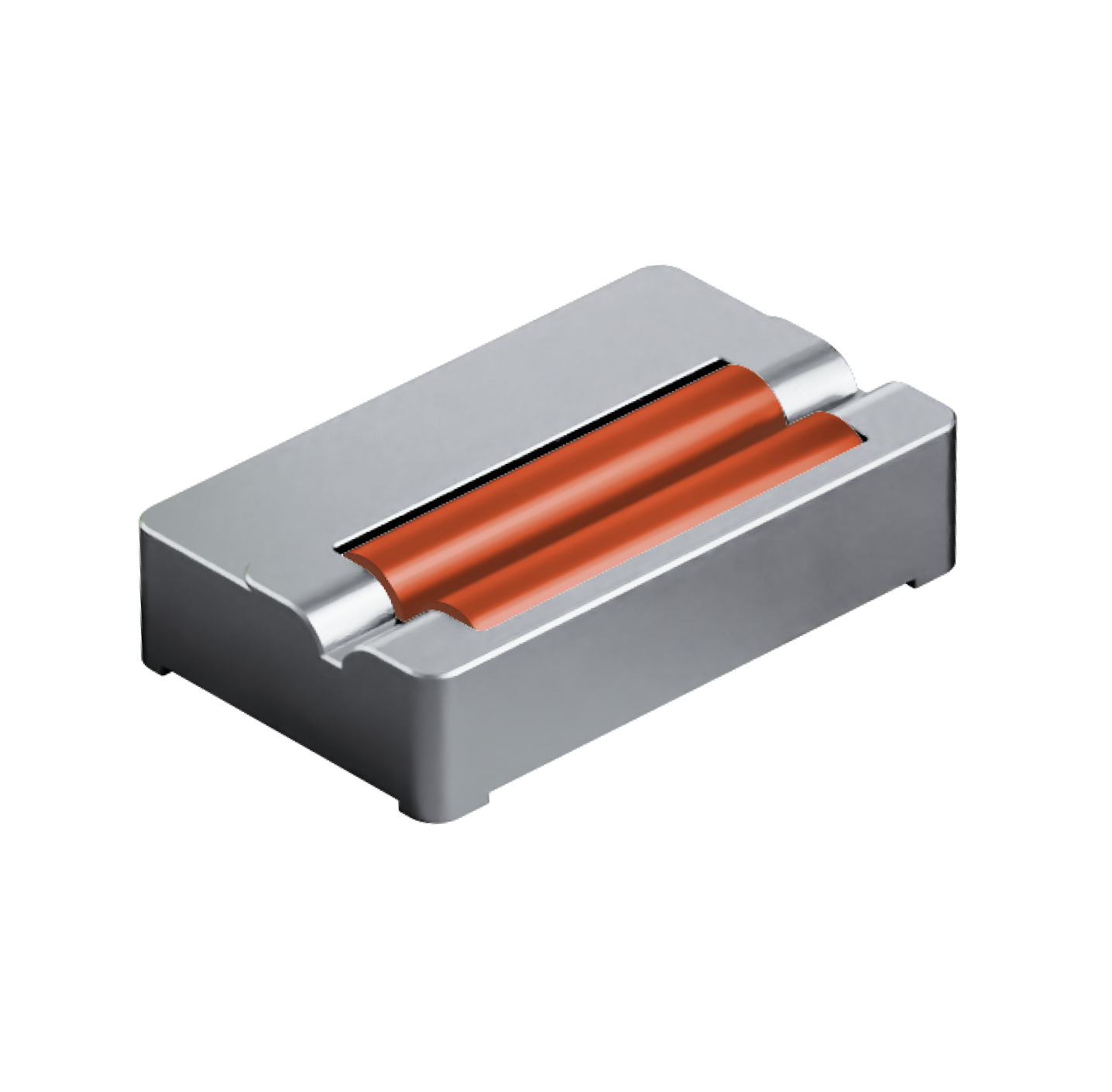

The laser marking machine typically includes a laser source, a set of mirrors or lenses to focus the laser beam, and a control system to direct the beam onto the material. The material is typically placed on a moving table or conveyor belt, which allows the laser beam to be directed onto different areas of the material as it moves through the machine.

The laser used can vary depending on the application, but the most common types are CO2, YAG, and Fiber lasers.

There are different types of laser marking machines, such as:

- CO2 laser marking machine, which is suitable for marking on non-metallic materials such as plastic, wood, paper and leather.

- YAG laser marking machine, which is suitable for marking on metal and non-metal materials.

- Fiber laser marking machine, which is suitable for marking on metal and some non-metal materials and is known for its high speed and precision.

The type of laser used and the specific settings used will affect the final result of the mark.