1.What kind of laser can engrave stainless steel?

-

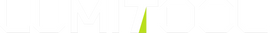

Fiber laser

-

CO2 laser

-

Nd:YAG laser

-

Green laser

2.How to engrave stainless steel with a laser? A step-by-step guide

- Step 1: Preparation

- Step 2: Design pattern

- Step 3: Set up the laser engraver

- Step 4: Engraving process

- Step 5: Post-processing

- Step 6: Maintain the equipment

3.Application of stainless steel engraving

- 1. Personalized Gifts

- Customized items: such as customized key chains, bracelets, watches and cups, consumers can choose to engrave names, dates or special patterns.

- Souvenirs: Used to make commemorative gifts for weddings, birthdays or other special occasions.

- 2.Industrial Marking

- Serial numbers and barcodes: Used for permanent marking on equipment, machines and tools for tracking and management.

- Safety signs: Used to mark safety information and warning signs in factories and construction sites.

- 3.Architecture and Decoration

- Building panels: Stainless steel engraving can be used on the facade of a building to create a unique visual effect.

- Interior decoration: Engraved stainless steel elements can be used for wall decoration, lighting design and furniture manufacturing.

- 4.Artworks

- Sculptures: Artists use stainless steel engraving to create large-scale sculptures and installation art, showing modern art style.

- Wall-mounted fixtures: Stainless steel engravings can be made into wall-mounted works to beautify the indoor environment.

- 5.Advertising and signage

- Commercial signage: Signs and signs for stores, restaurants and businesses, engraved stainless steel signs are durable and modern.

- Exhibition displays: Used in booth design for exhibitions and fairs to attract customers' attention.

- 6.Catering and kitchenware

- Personalized kitchenware: Such as customized stainless steel knives, tableware, etc., suitable for high-end catering and cooking enthusiasts.

- Menu boards and signs: Use engraved stainless steel menu boards and drink signs in restaurants.

- 7. Medical equipment

- Medical marking: Engraving on medical equipment, instruments and tools for identification and tracking.

- Devices: The housing and frame of some medical devices can be engraved with stainless steel, which is hygienic and durable.

- 8. Electronic products

- Housing design: The housing of high-end electronic products (such as mobile phones and laptops) can be engraved with stainless steel, providing a combination of beauty and durability.

- Brand identification: Engraving logos and brand names on electronic devices to enhance brand image.

- 9. Transportation

- Automobile and motorcycle accessories: Stainless steel engraving is used to customize decorative parts, logos and accessories for automobiles and motorcycles.

- Aerospace and Navigation: High-strength stainless steel engraving is used in components of spacecraft and ships to ensure safety and performance.

4.FAQs About Stainless Steel Engraving

- Q1:What is the best type of laser for stainless steel engraving?

- A1: Fiber laser is the best choice because it provides high efficiency and high precision, especially suitable for engraving metal materials, and can achieve very detailed and deep pattern engraving.

- Q2:What are the limitations of material thickness for stainless steel engraving?

- A2: The material thickness of stainless steel engraving depends on the type and power of the laser used. Generally speaking, fiber lasers can process stainless steel from thin to a few millimeters thick, while for thicker materials, higher power lasers may be required.

- Q3:What are the common applications for stainless steel engraving?

- A3: Common applications for stainless steel engraving include personalized gifts (such as customized mugs, key chains), industrial markings (such as equipment serial numbers, safety logos), and artwork creation (such as sculptures and installation art).

- Q4:What safety precautions should be taken during engraving?

- A4: During the engraving process, be sure to wear protective glasses, gloves, and ensure that the working area is well ventilated. In addition, pay attention to the equipment operating procedures to avoid accidental injuries.

- Q5:How to maintain the engraving machine to ensure its efficiency?

- A5: Clean the laser head and lens regularly, check the cooling system, calibrate the machine regularly, and perform maintenance according to the manufacturer's recommendations to ensure the efficient operation of the engraving machine.

- Q6:How to treat the stainless steel surface after engraving?

- A6: After engraving, you can clean the stainless steel surface with water or alcohol to remove residual smoke and dirt. In addition, you can use stainless steel cleaner for maintenance to maintain the gloss of the surface.

- Q7:Is there a size limit for the engraved pattern or text?

- A7: The size of the engraved pattern and text usually depends on the working area of the laser machine and the fineness of the laser beam. More complex and delicate designs may have certain limitations, so the feasibility of actual operation should be considered when designing.

- Q8:What is the cost of stainless steel engraving?

- A8: The cost of stainless steel engraving depends on a variety of factors, including material type, engraving complexity, how long the engraving machine has been used, and the details of the design. Custom projects usually cost more than mass production.

- Q9:Is stainless steel suitable for engraving?

- A9: Yes, stainless steel is an excellent engraving material because it is durable, corrosion-resistant, and able to retain fine engraving patterns. Its hardness and strength make it suitable for a variety of engraving techniques, including laser engraving, rotary engraving, and chemical etching. The engraving effect is long-lasting and can leave precise and permanent marks on the stainless steel surface.

- Q10:Will stainless steel rust after engraving?

- A10: Stainless steel itself has good corrosion resistance, but if the surface is scratched or improperly handled during engraving, it may cause rust. Therefore, proper surface treatment and maintenance are the key to ensure its long-term durability.

5.Conclusion