1.What is Laser Engraving Wood?

Wood cutting and engraving are two of the most common applications for laser machines because they can process a wide variety of wood products. From large cabinets to small picture frames and knife handles. Whether the material you are dealing with is hardwood, veneer, inlay, MDF, plywood, walnut, alder or cherry, you can use a laser system to engrave intricate and amazing patterns.

2.How does laser engraving work on wood?

The localized thermal effects of a high-energy laser beam are used to create permanent marks on wood surfaces by ablation (removal of material) and/or carbonization (change of color).

3.What wooden products can be made using a wood laser cutting machine?

Photo Engraving

A picture is worth a thousand words, and an engraved photo is worth a thousand words! Rich mahogany or natural pine are perfect ways to engrave your customers' photos and memories to remember the past.

Inlays

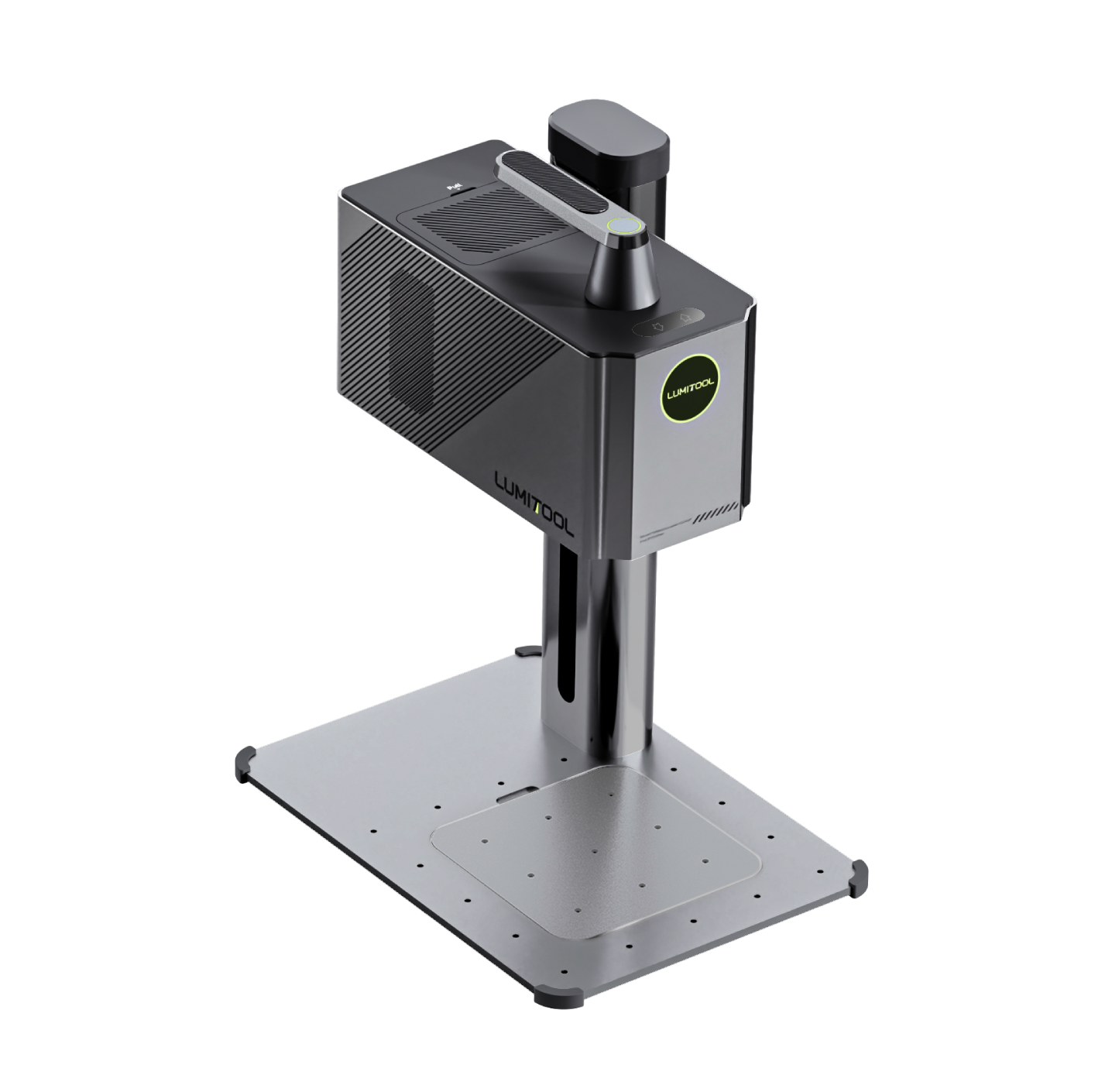

Use the cutting and engraving capabilities of the LumiTool F28 to create beautiful inlays for cabinets, awards, guitars, and more.

Prototyping

For projects you need to complete quickly, a laser system can significantly speed up your workflow. By quickly cutting materials like MDF and plywood, you can go from idea to prototype faster than ever before. Plus, because lasers let you process materials in nearly any size or shape, it's easy to use leftover wood from a previous project!

Personalization

Laser systems can help customize products to create something unique and better. Turn a great piece into a great gift by customizing an award, skateboard, phone case, guitar, or any other item.

4.Can a dual-light laser marking machine engrave wood?

To cut wood with a laser, you need a laser cutter, which greatly simplifies the process and ensures high-precision results. With so many types available on the market (such as diode, CO2, and fiber laser engravers), users often ask, "Which laser is best for cutting wood?" or "What machine should I choose for cutting wood?"

The answer depends on your specific needs. For home users or small wood cutting projects, a dual-light laser engraver (usually combining CO2 and diode) is usually the best choice. It is easy to use and more cost-effective than other laser devices for wood cutting.

Step 1: Choose your material - wood

Choosing the right material is crucial for laser cutting wood. Different materials require specific laser settings to ensure a precise cut. Also, be sure to make sure your wood is laser safe to avoid any potential safety hazards.

Step 2: Choose the right wood laser cutter

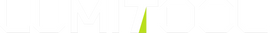

We recommend the LumiTool F28, which is perfect for wood laser cutting projects.

Step 3: Prepare your design for cutting

Import the shape or design you want to cut on the wood surface. Consider the size, shape, and other details.

Step 4: Set up your wood laser cutter

First, make sure the cutter is turned on, then connect the laser cutter to your computer or mobile device using a suitable interface (USB cable, Bluetooth, etc.).

Connect your LumiTool F28 device

Second, open the LumiTool F28 design space and load your design. (JPG/PNG/G-Code/SVG, etc. are all acceptable)

Third, place the object in the designated work area and check if the laser lens is in focus. There are two ways to check.

If you choose LumiTool F28, the first method is to use a ruler to measure the distance between the wood surface and the machine. The recommended distance in red light mode is 22 cm or 220 mm. The recommended distance in blue light mode is 22.9 cm or 229 mm.

Alternatively, you can determine the correct focal distance by judging whether the two red dots emitted by the machine overlap. This ensures precise focus for the best cutting and engraving results.

Fourth, you need to open the "Preview" mode to see if the design fits perfectly with the wood surface. If it doesn't fit, adjust its size and position to match the material size.

Finally, access the software's laser settings to adjust parameters such as power, speed, and resolution according to the characteristics of the wood and the complexity of your design.

Step 5: Start cutting wood with the laser right away

Double-check everything to avoid mistakes. Then, press the "Start" button and watch the magic happen. The laser brings your design to life. Pay close attention, and you're all set!

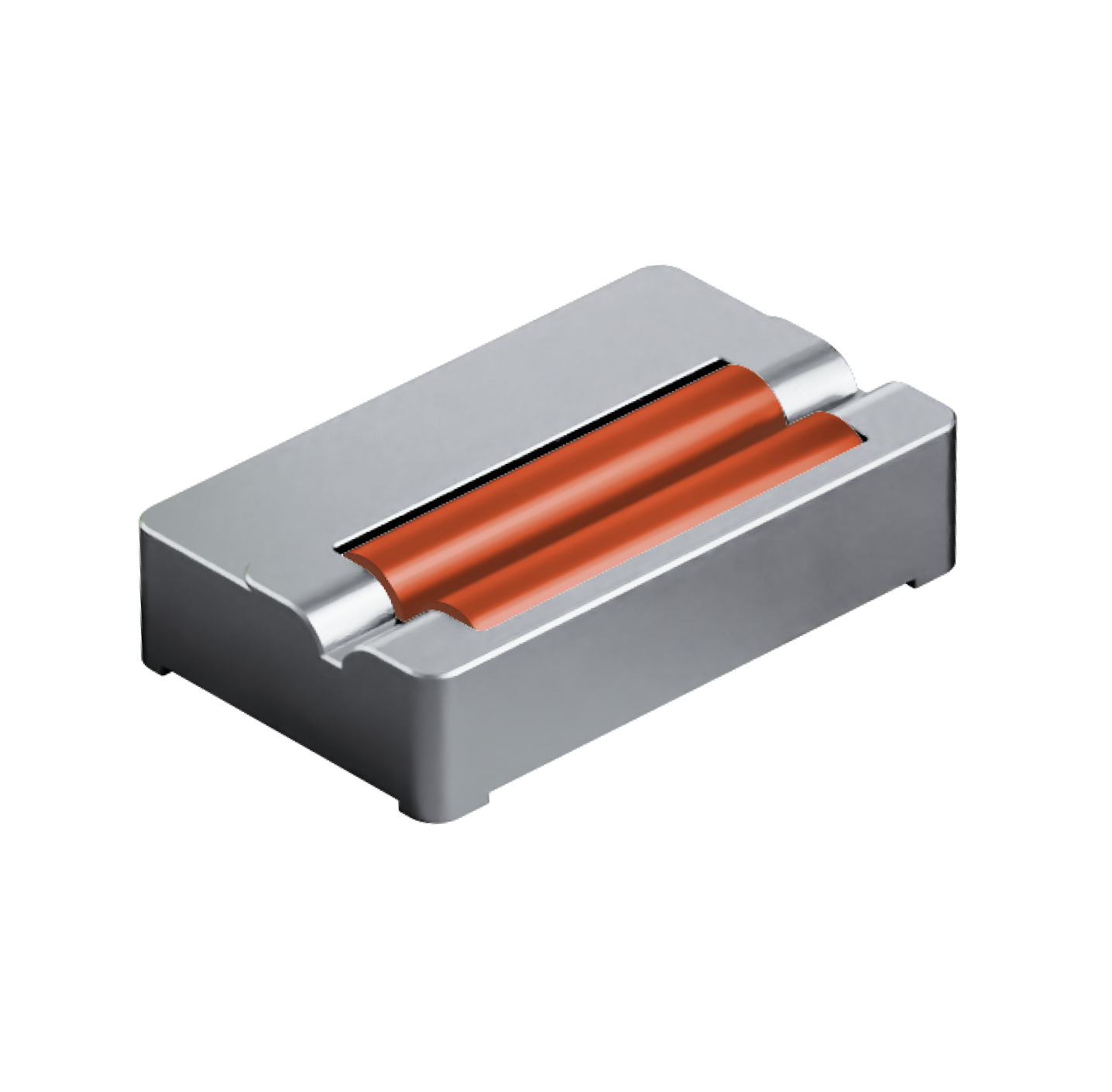

When operating a laser engraving and cutting machine using a 450 nm blue laser, it is recommended to wear goggles or use a laser shield to protect your eyes and body from potential damage, as blue lasers can be risky.

Also, be aware that toxic fumes may be produced during wood laser engraving. Wearing a mask or using an air purifier is essential for safety.

Conclusion:

In summary, wood laser cutting technology has reshaped the processing boundaries of wood materials with its outstanding diversity and precision. It can efficiently transform complex designs into functional products, produce finished products with smooth edges and precise patterns, and open up unlimited possibilities for artistic creation, industrial manufacturing and personal projects.