1.Material properties of laser engraved silver

Silver is an elegant metal with good conductivity and corrosion resistance, and is often used to make jewelry, decorations and high-end gifts. The luster and plasticity of silver make it popular in craft design. Laser engraving technology can achieve high-precision and high-detail engraving on the silver surface, creating exquisite patterns and designs.

2.Working principle of laser engraving silver

The basic principle of laser engraving silver is to react with the surface of silver through a high-energy laser beam. When the laser beam hits the surface of silver, the laser energy will evaporate or melt the metal surface, forming an engraving or pattern. This process can not only cut on silver, but also achieve a detailed engraving effect, which is suitable for making personalized jewelry, souvenirs and gifts.

-

Choose the right laser silver material

There are many types of silver materials for laser engraving, and choosing the right silver material is crucial to the engraving effect. You can choose according to the following criteria:

-

Silver purity:

-

925 silver (sterling silver): contains 92.5% silver, usually used in high-end jewelry, with good engraving effect

-

Silver alloy: alloys of other metals such as copper, which are lower in cost but have relatively poor engraving effects.

-

Surface treatment:

-

Polished silver: smooth surface is suitable for high-precision engraving and can show excellent details.

-

Frosted silver: can provide different visual effects and is suitable for specific design styles.

3.Steps of laser engraving silver

The process of laser engraving silver can be divided into the following key steps:

-

Design preparation:

-

Use image processing software (such as Adobe Illustrator, CorelDRAW, etc.) to create or import design files to ensure that the design meets the requirements of laser engraving, common formats such as SVG or DXF.

-

Material preparation:

-

Select the appropriate silver material and ensure that its size meets the design requirements. Clean the silver surface to remove oxide layers, grease or stains to ensure clear engraving.

-

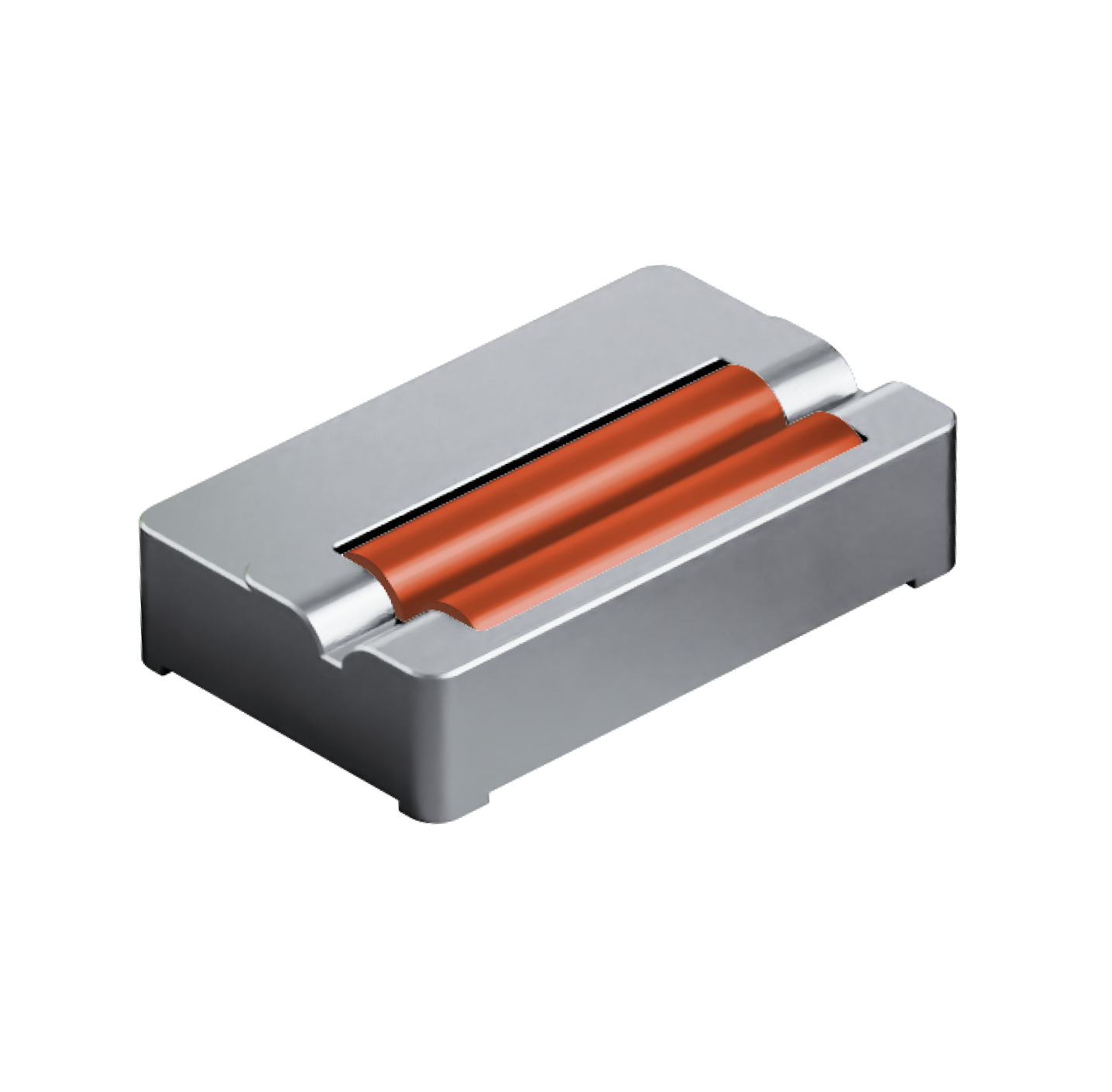

Laser engraving machine settings:

-

Set parameters according to the specifications and requirements of the laser engraving machine, including laser power, engraving speed and number of repetitions, which are crucial to the final engraving effect.

-

Focus Adjustment:

-

Adjust the focus of the laser engraver according to the thickness of the silver material to ensure that the laser can accurately focus on the surface of the material to obtain the best engraving effect.

-

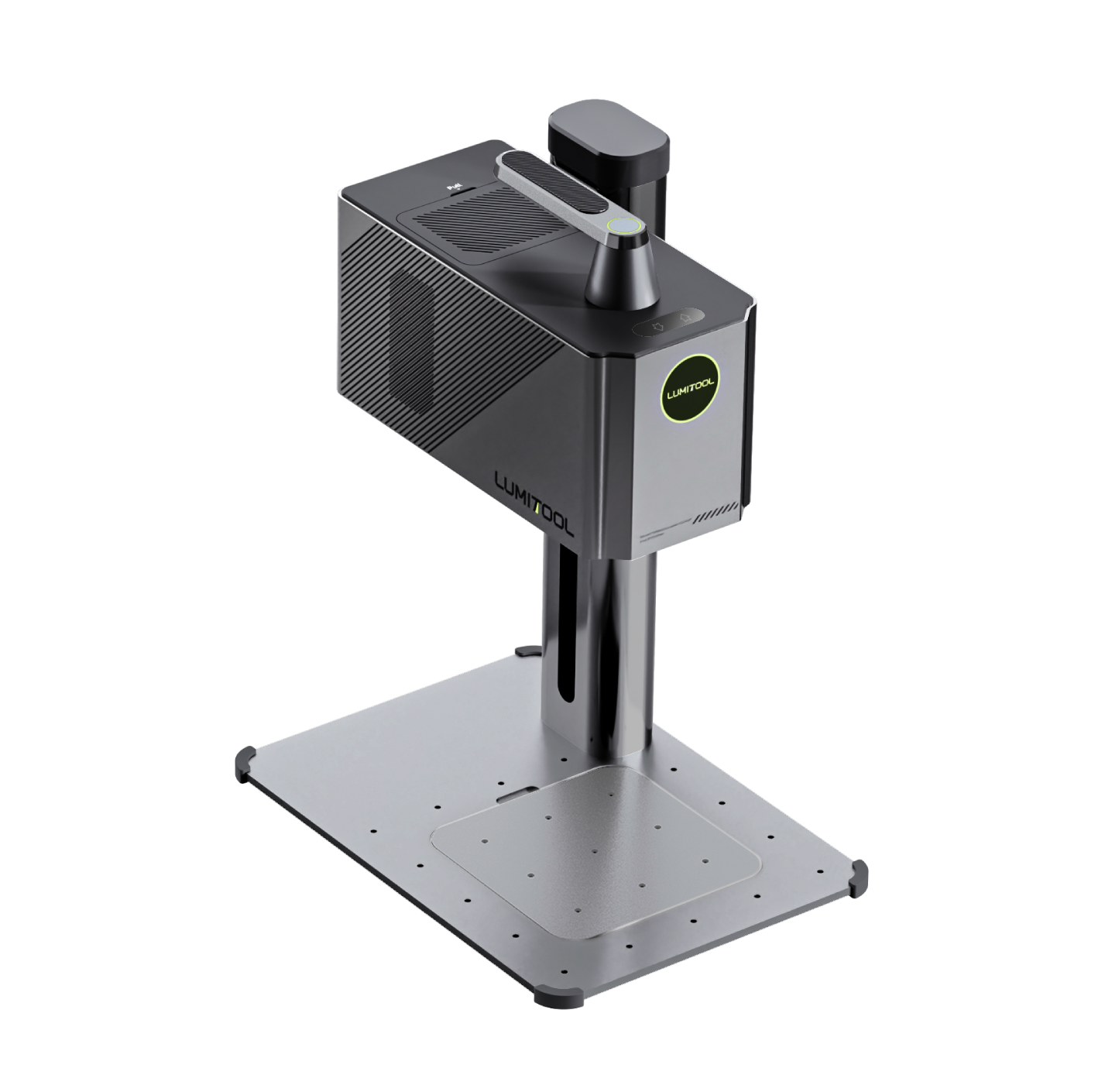

Material Positioning and Fixing:

-

Place the silver material firmly on the workbench of the laser engraver to ensure that it is accurately positioned to avoid displacement during the engraving process.

-

Start Engraving:

-

Start the laser engraver and observe the laser beam gradually etching or cutting the silver material along the preset path. Depending on the complexity of the design, the engraving process may take different times.

-

Post-processing Inspection:

-

After engraving, check the engraving effect of the silver. If defects or areas that need to be trimmed are found, appropriate trimming and polishing can be performed to improve the texture and visual effect.

-

Cleaning the Work Area:

-

Clean up the waste and fumes generated during the laser engraving process to ensure a clean and safe environment. Dispose of waste and exhaust properly according to local regulations.

4.FAQs About Acrylic Engraving

- Q1:What is the best material for laser engraving silver?

- A1: The most commonly used material is 925 silver (sterling silver) because it contains 92.5% silver, has good engraving effects and durability. Other silver alloys can also be used, but their engraving effects may not be as good as 925 silver.

- Q2: Will laser engraving silver affect its properties?

- A2: The laser engraving process generates heat on the surface of the silver, which may cause a small range of oxidation or discoloration, but it does not usually affect the basic properties of the silver. Proper post-treatment can restore its luster.

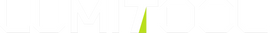

- Q3:What is the best type of laser machine for laser engraving silver?

- A3: Fiber laser engravers are the best choice for engraving silver. They have high energy density and precise focusing capabilities, and are able to produce detailed patterns on the metal surface.

- Q4:Is the engraving effect long-lasting?

- A4: The effect of laser engraving is generally long-lasting. However, the surface of silver products may change over time due to wear or oxidation, so proper care and cleaning can extend its beauty and life.

- Q5: How fine are the details of laser engraved silver?

- A5: Laser engraving is capable of extremely high precision, often engraving fine details and complex patterns with micron-level accuracy, which allows designers to create very delicate and personalized works.

- Q6:How fast is laser engraving silver?

- A6: The speed of engraving depends on the complexity of the design, the power of the engraver, and the settings. Simple designs may be completed in a few minutes, while complex patterns may take longer.

- Q7: What post-processing is required after engraving?

- A7: After engraving, cleaning is usually required to remove residual metal powder and fumes. It can be gently wiped with a soft cloth and metal cleaner, and polished if necessary to restore the gloss.

- Q8:What are the common problems with laser engraving silver?

- A8:Discoloration: Due to heat, the engraved area may appear discolored or oxidized.

- Loss of details: If the laser parameters are not set correctly, details may be lost.

- Material loss: There may be unexpected material loss when engraving, especially at the edges.

5.Conclusion

Laser engraving silver is a delicate and highly personalized process that can be used on a variety of products including jewelry, souvenirs, and more. Understanding common problems and solutions can help you reduce problems during the engraving process and improve efficiency and final results. If there are other specific questions or needs, feel free to provide more information so that we can better assist you.