People are increasingly choosing fiber laser cutting machines over CO2 laser cutting machines for following reasons:

-

Speed: Fiber lasers are incredibly fast. They cut through materials with lightning speed, allowing them to get more done in less time.

-

Power Efficiency: Fiber lasers are much more energy-efficient. They consume less power, which means lower operating costs and a greener approach.

-

Precision Prowess: Fiber lasers offer exceptional precision, making intricate cuts with razor-sharp accuracy, perfect for detailed designs and fine-tuned work.

-

Low Maintenance: These machines require minimal upkeep, reducing downtime and ensuring that the machine is always up and running at peak performance.

-

Minimal Wastage: Thanks to their precision, fiber lasers minimize material wastage, saving you money and resources.

-

Quieter Operations: Fiber lasers operate more quietly compared to their CO2 counterparts, creating a more comfortable working environment.

-

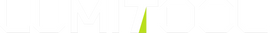

Compact and Portable: They come in a smaller, more manageable size, making them ideal for businesses with limited space.

-

Enhanced Safety: Fiber lasers offer improved safety features, reducing the risk of accidents and ensuring a secure work environment.