1.Fiber laser markers can produce different colors on stainless steel through a process called laser marking or laser engraving, which involves the following mechanisms:

- 1. Heat Affected Zone (HAZ)

When a fiber laser is used to mark stainless steel, it produces localized heat that affects the surface of the material. This heat causes oxidation, which changes the color of the stainless steel. The specific color produced depends on the temperature reached during the marking process:

Black: Achieved by melting the surface and causing it to oxidize.

Brown: Produced at a slightly lower temperature than black.

Gold or yellow: Produced at even lower temperatures, usually through controlled oxidation.

Blue and purple: These colors appear at specific temperatures (around 300-500°C) and are produced by thin film interference.

- 2. Marking Speed and Power Settings

The color produced can also be affected by the power setting of the laser and the speed at which the laser moves across the surface. The slower the speed and the higher the power, the darker the mark and the different colors due to more extensive heating and oxidation.

- 3. Surface Preparation

The initial condition of the stainless steel surface can also affect the results. Due to variations in light reflection and absorption, polished surfaces may produce different colors than rough surfaces.

- 4. Layering Technology

Some advanced fiber laser marking machines can create a multi-layer effect that produces different colors by strategically applying different levels of power and speed in different areas.

2.FAQs about fiber laser marking machines producing different colors on stainless steel

- Q1:How does a fiber laser marking machine produce colors on stainless steel?

- A1:Fiber laser marking machines adjust the power, speed, and frequency of the laser to form an oxide film on the surface of stainless steel, thereby producing different color effects at different temperatures.

- Q2:What colors can be produced when stainless steel is marked?

- A2:Stainless steel can be produced in a variety of colors by fiber laser marking, including black, blue, purple, gold, red, etc. The specific color depends on the laser parameters and the surface treatment of the material.

- Q3:What is the relationship between the depth of the marking and the color?

- A3:The depth of the marking affects the presentation of the color. Generally, lighter markings produce brighter colors, while darker markings may cause the color to darken or disappear.

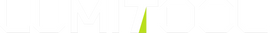

- Q4;How suitable is the fiber laser marking machine for stainless steel?

- A4:Fiber laser marking machines are very suitable for stainless steel materials, providing high-quality, durable marking effects, and are ideal for industrial marking.

- Q5:What are the parameter settings for producing different colors?

- A5:The production of different colors requires adjustment of laser power, speed and frequency. Generally speaking, lower power and moderate speed can produce bright colors, while higher power is suitable for dark or black colors.

- Q6:Will the color effect be different on different types of stainless steel?

- A6:Yes, different types of stainless steel (such as 304, 316, etc.) will affect the effect of laser marking, resulting in different colors and visual effects.

- Q7:How durable is the color?

- A7:The colors produced by fiber laser marking are generally durable and can resist wear, corrosion and oxidation, but the specific durability also depends on post-processing and the use environment.

- Q8:What safety measures need to be considered during the marking process?

- A8:When operating the fiber laser marking machine, please be sure to wear laser protection glasses and operate in a well-ventilated environment to avoid the hazards of laser radiation and harmful gases.

- Q9:How do I choose the right laser parameters to get the ideal color?

- A9:Choosing the right laser parameters usually requires experimentation to find the best combination of power, speed, and frequency. Depending on the material and the desired effect, make appropriate adjustments.

- Q10:Can color marking be done on stainless steel?

- A10:Yes, fiber laser marking machines can achieve color marking on stainless steel. By adjusting laser parameters and technology, a variety of colors can be achieved, which can be used for brand logos or artistic designs.

These FAQs help understand the application of fiber laser marking machines in stainless steel marking and how to produce rich color effects.