When it comes to engraving, there are two main techniques that are widely used: laser engraving and machine engraving. Whether you are a hobbyist or a professional, understanding the differences between the two methods will help you choose the right one for your project. Both techniques have their advantages and disadvantages, depending on the type of material, the level of detail required, and the budget of the project. This guide will break down each method, focusing on how they work, the equipment used, and their main applications. Write sentences similar to this.

1.What is laser engraving?

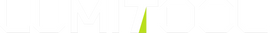

- Laser engraving is a technology that uses high-energy laser beams to accurately cut and engrave on the surface of various materials. The basic principle is to evaporate, ablate or melt the surface of the material through the laser to form the desired pattern, text or shape. The laser engraving machine is usually composed of a laser generator, an optical system and a CNC system, which can achieve complex designs and maintain high precision.

- Laser engraving machines use a series of steps to precisely engrave a design onto a material's surface. First, the user creates or imports a pattern using design software, then places the material on the machine and adjusts the power and speed of the laser. The laser beam from the laser generator is focused onto the material and moves along a set path, rapidly evaporating or ablating the material to form the engraved pattern. Finally, after the engraving is complete, it is cleaned and inspected to ensure that the engraving is as expected. This technology is suitable for a wide range of materials and can achieve high precision and complex designs.

- Key Components of a Laser Engraving Machine:

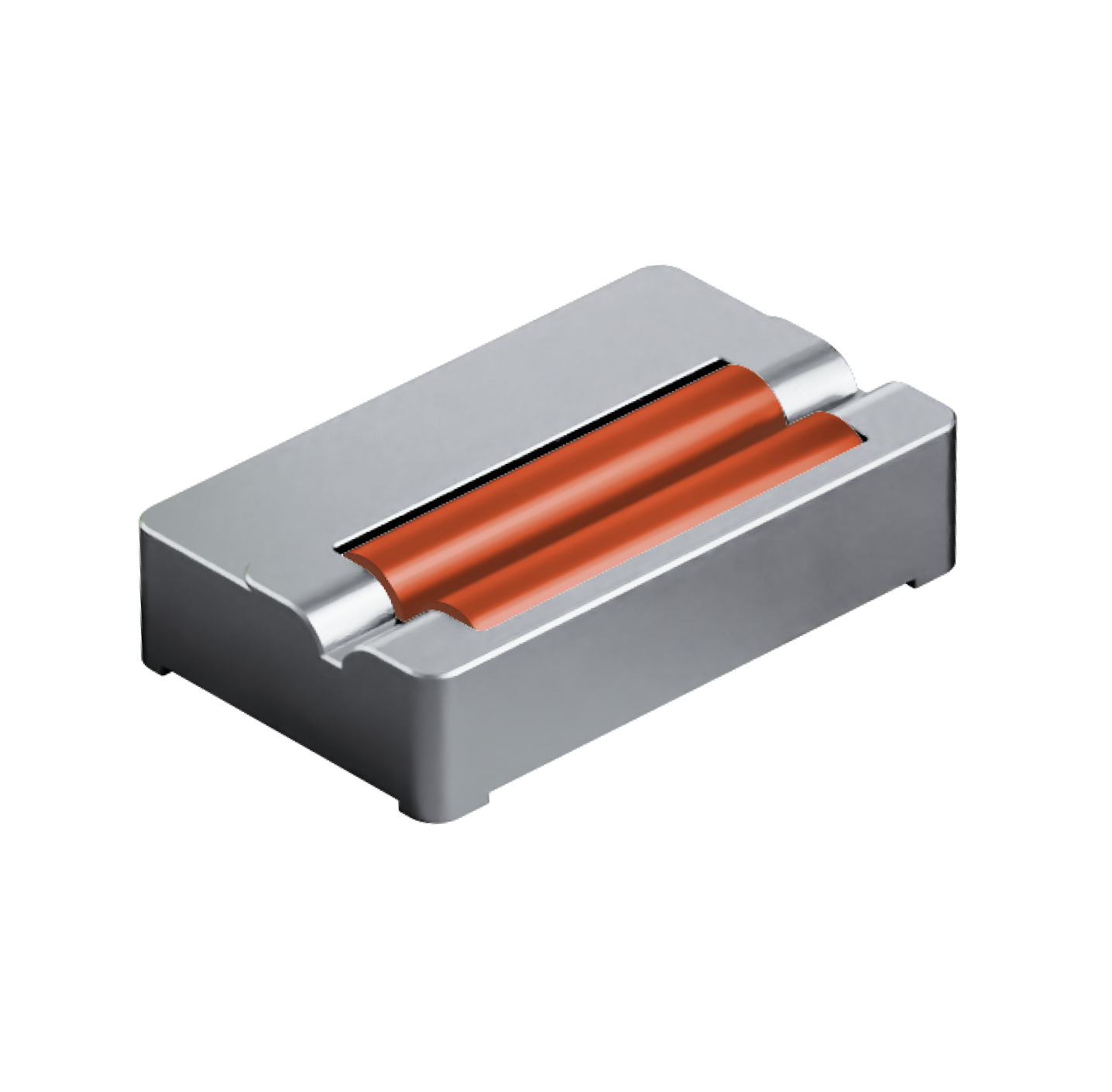

Laser Source: The heart of the machine. Types include CO2 lasers for softer materials, such as wood and leather, and fiber lasers for metals.

Controller: Software that interprets the design file (such as a vector or image) and directs the movement of the laser.

Optical System: Guides and focuses the laser beam to a precise point on the material.

- Advantages of Laser Engraving:

Accuracy: Great for fine details and intricate patterns.

Speed: Laser engraving can be fast, depending on the material and depth required.

Versatility: Works on a wide variety of materials, such as metal, wood, plastic, acrylic, and glass.

Non-Contact Process: The laser never physically touches the material, which reduces wear and tear on the machine.

- Disadvantages of Laser Engraving:

Cost: High-quality laser engravers can be expensive, although costs have fallen in recent years.

Material Limitations: While lasers work well with a wide variety of materials, some metals and reflective surfaces can be difficult to engrave with certain types of lasers.

Fume Extraction: When engraving certain materials, such as acrylic or plastic, fumes are produced, requiring proper ventilation.

2.What is machine engraving?

- Machine engraving is a traditional processing technology that uses a rotary tool or mechanical engraving machine to engrave on the surface of the material. It is suitable for application scenarios that require deeper cutting and more durable engraving effects. This method is able to create fine patterns and depth effects on a variety of materials and is widely used in crafts, decoration, manufacturing and other fields.

- The working principle of the machine engraving machine is to remove materials by physical means. The engraver uses a cutting tool, usually a rotary drill or a special engraving pen, to accurately depict the design pattern. These machines are usually controlled by a computer numerical control (CNC) system, making the engraving process not only efficient, but also extremely accurate and repeatable. Through preset programs, the engraving machine can automatically complete complex engraving tasks, thereby improving production efficiency and ensuring the consistency of engraving quality. The advantage of this technology is that it can handle a variety of materials, including wood, plastic, metal, etc., providing a wide range of possibilities for creation.

- Key Components of a Machine Engraving Machine:

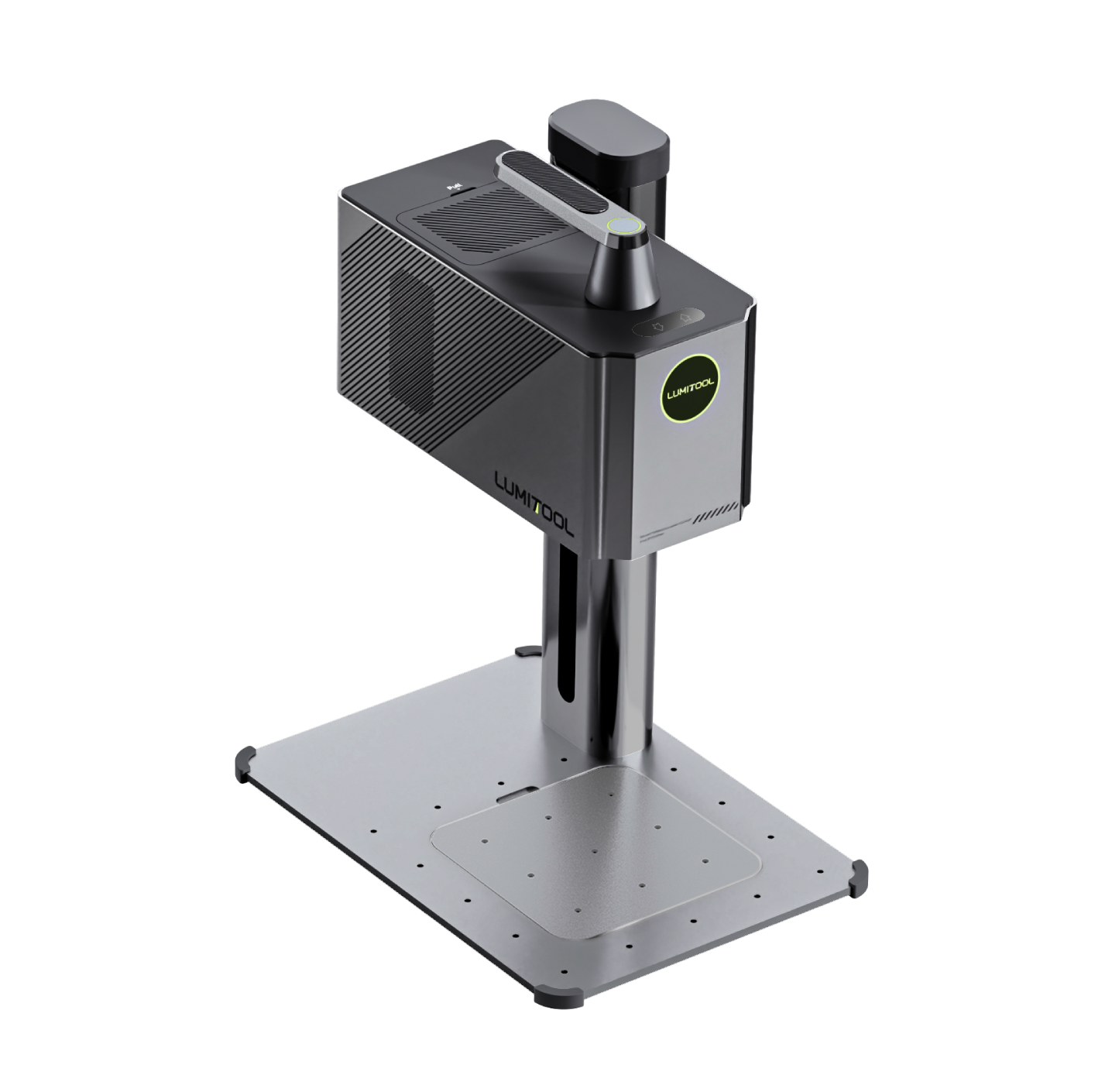

Cutting Tool: A rotating drill or stylus that engraves the material.

Spindle: A rotating axis that powers the cutting tool.

CNC System: A computer system that directs the spindle's motion according to the design file.

- Advantages of Machine Engraving:

Depth: Machine engraving can create deeper, more durable engravings, which is critical for certain applications such as mold making and industrial parts.

Versatility for Metals: Especially useful for harder materials such as steel, brass, and other metals.

Affordability: While high-end machine engravers can be expensive, entry-level models are generally more affordable than laser engravers.

- Disadvantages of Machine Engraving:

Lower Accuracy in Fine Detail: Machine engraving may not achieve the same level of fine detail as laser engraving.

Contact Process: The cutting tool comes into direct contact with the material, which can cause wear on the tool and the surface.

Slower: Machine engraving can be slower than laser engraving, especially when working with intricate designs.

3.Laser Engraving

Accuracy: Extremely accurate, ideal for intricate designs and fine details.

Speed: Faster for most applications, especially detailed work.

Material Versatility: Works on a wide range of materials (wood, acrylic, metal, plastic).

Cost: The upfront cost of the machine is higher, but ongoing maintenance costs are lower.

Durability of Engraving: Typically shallow, best suited for decorative purposes.

Maintenance: Low, non-contact process means minimal wear and tear on the machine.

4.Machine Engraving

Precision: Less accurate, better suited for less deep, less detailed cuts.

Speed: Slower, especially on hard metals or thicker materials.

Material Versatility: Mostly used for harder materials like metal and stone.

Cost: Lower initial cost, but tools may wear out faster.

Durability of Engraving: Allows for deep, long-lasting engravings.

Maintenance: Higher maintenance costs, as tools wear out quickly.

5.How to choose between laser and machine engraving

When choosing between laser engraving and machine engraving, there are several factors to consider, including material type, design complexity, engraving depth, cost, production efficiency, and end use. Here are some key considerations to help you make your choice:

-

Material type

Laser engraving: Suitable for a variety of materials, such as wood, leather, paper, acrylic, and some metals (such as aluminum), but limited processing capabilities for some hard metals.

Machine engraving: Generally suitable for a wider range of materials, including hard metals, stone, and plastics, and is particularly suitable for applications that require a larger cutting depth.

-

Design complexity

Laser engraving: Ideal for fine and complex patterns, capable of handling high-detail designs, and suitable for projects that require subtle engraving or graphics.

Machine engraving: Can also achieve complex designs, but may not be as fine in detail as laser engraving, and is mainly used in situations where deeper cutting is required.

-

Cutting depth and effect

Laser engraving: Mainly used for surface treatment and shallow engraving. If deep engraving is required, the cutting ability of the laser may be limited.

Machine engraving: It can achieve deeper cutting effects, suitable for greater material removal and more durable engraving.

-

Cost and equipment investment

Laser engraving machine: The initial investment may be high, but the maintenance cost is relatively low, suitable for small-scale production or personalized customization.

Machine engraving machine: The equipment cost is usually not low, and the maintenance and replacement requirements of the tool are high, but it may be more cost-effective in large-scale production.

-

Production efficiency

Laser engraving: It is usually fast, suitable for large-scale production, and can quickly switch between different designs.

Machine engraving: It may be slow, especially when dealing with complex patterns, but it can provide more stable processing quality in some cases.