1.What is metal laser engraving and how does it work?

2.What are the best ways to engrave metal?

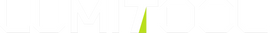

Method 1: Laser Engraving Metal

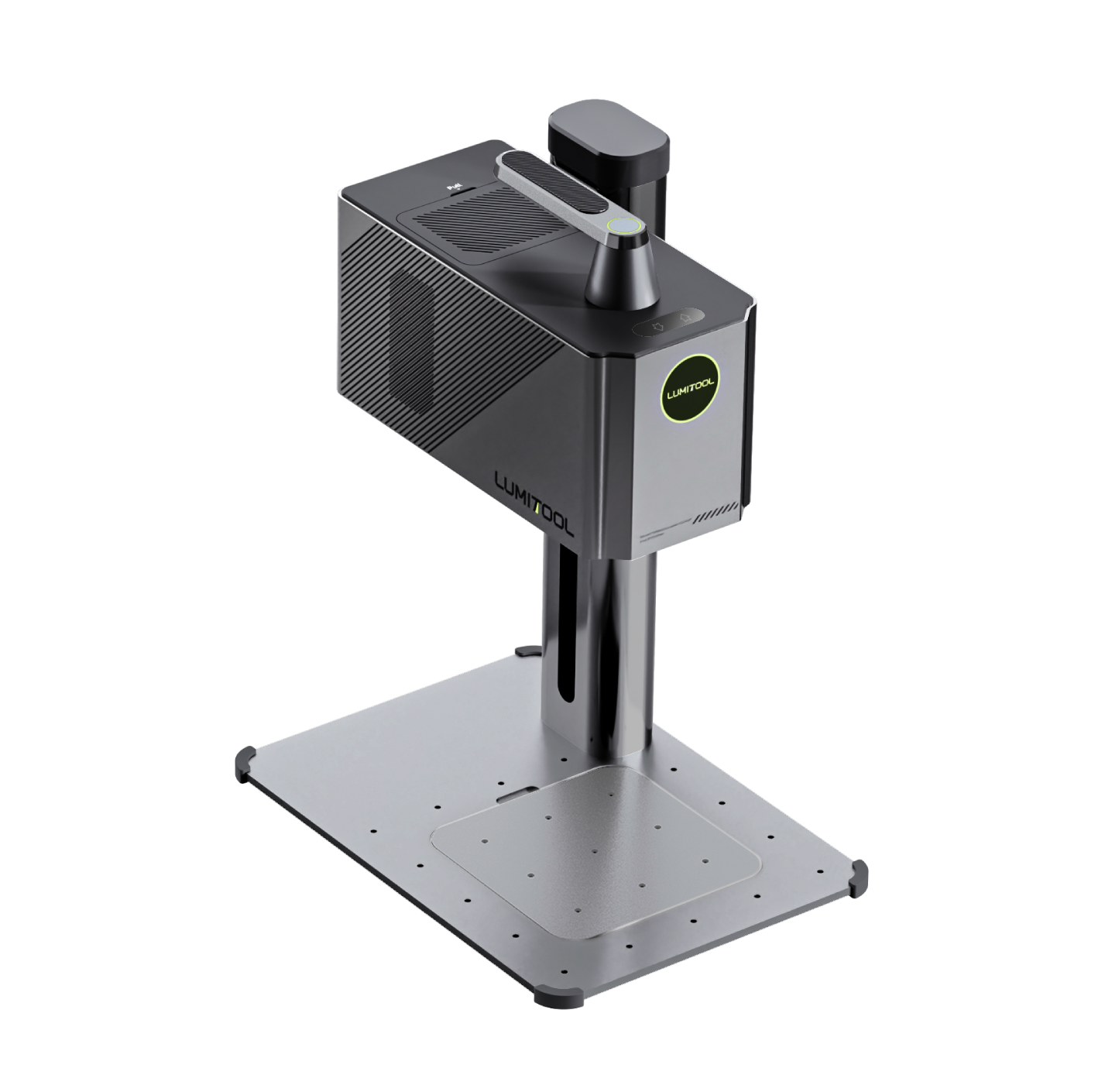

Method 2: Rotary Engraving Metal

-

Rotary tool (such as Dremel): This is a handheld tool known for its versatile engraving capabilities. It is small, powerful, and has an adjustable speed, suitable for different types of engraving drill bits.

-

Drill bits: Hard and durable diamond drill bits are usually used for metal engraving, and carbide and stainless steel drill bits can also be used.

-

Jigs: Depending on the needs, a jig may be required to hold the metal workpiece, but in some cases, a jig is not necessary.

-

Clean the metal surface to be engraved with alcohol to ensure that it is clean and dust-free.

-

Draft the design you want on a vinyl sticker so that it can be easily applied to the metal surface. You can also use the printing method to transfer the design to the metal.

-

Apply the vinyl sticker to the metal and use a permanent marker to trace the outline of the design, then remove the sticker.

-

Insert the drill into the rotary tool and turn it on. For best results, use a diamond drill bit.

-

Start with a lower speed setting and gradually increase as needed. For metal, higher speeds are generally more effective.

-

Touch the tip of the engraving tool lightly to the metal and engrave in the design or pattern. Apply steady pressure, but not too much to avoid slipping. For deeper engravings, repeat the engraved design several times.

-

When you are done engraving, turn off the rotary tool. Use a soft brush or cloth to remove any metal shavings from the engraved pattern.

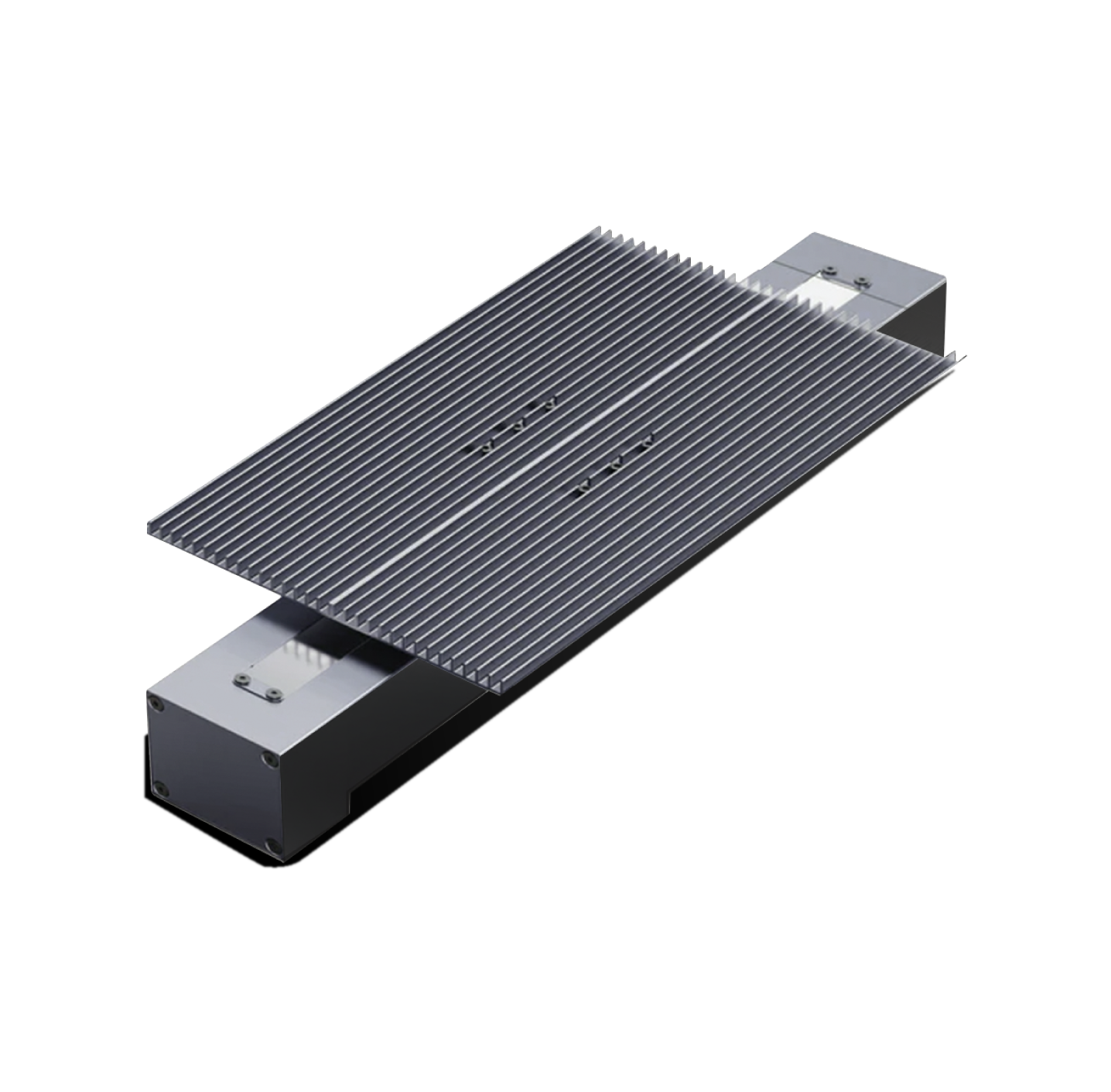

Method 3: CNC Engraving Metal

-

Planning and delivery of CNC super light engraving machine control system.

-

The number of movement settings for the carving, the light effect rate, and the speed harmonization rate.

-

Moving CNC flash engraving machine, the beginning of the process of engraving.

-

During the engraving process, the metal surface is irradiated with a strong beam of light.

-

After the carving is completed, the carving machine can be removed from the metal work.

Method 4: Hand Engraving Metal

-

Engraving knife: The engraving knife is the most basic tool used to cut, engrave and shape metal. It comes in various shapes and sizes, such as flat knives, bevel knives, round knives, etc. Engraving knives usually consist of a solid metal blade and a handle.

-

File: The file is used to shape and modify the surface of the metal after engraving. It comes in different shapes and finenesses and can be used to remove rough edges, adjust shapes and flatten surfaces.

-

Hammer: Hammers are used to strike and shape metal. Different types of hammers can be used to produce different effects, such as ball hammers, flat convex hammers, etc.

-

Chisel: Chisels are used to carve depth and texture into metal. It comes in different shapes and sizes and can be used to cut and engrave metal.

-

Pliers: Pliers are used to hold metal workpieces for engraving and handling. They can be handheld, pliers or clamps.

-

Cutting tools: Cutting tools such as saws, cutters, scissors, etc. can be used to cut metal and remove unwanted parts.

-

Sandpaper: Sandpaper is used to grind and polish the metal surface to make it smooth and consistent.

-

Pencil or erasable marker: Used to mark the outline of the design or pattern on the metal.

3.What metal materials can be engraved with laser engraving?

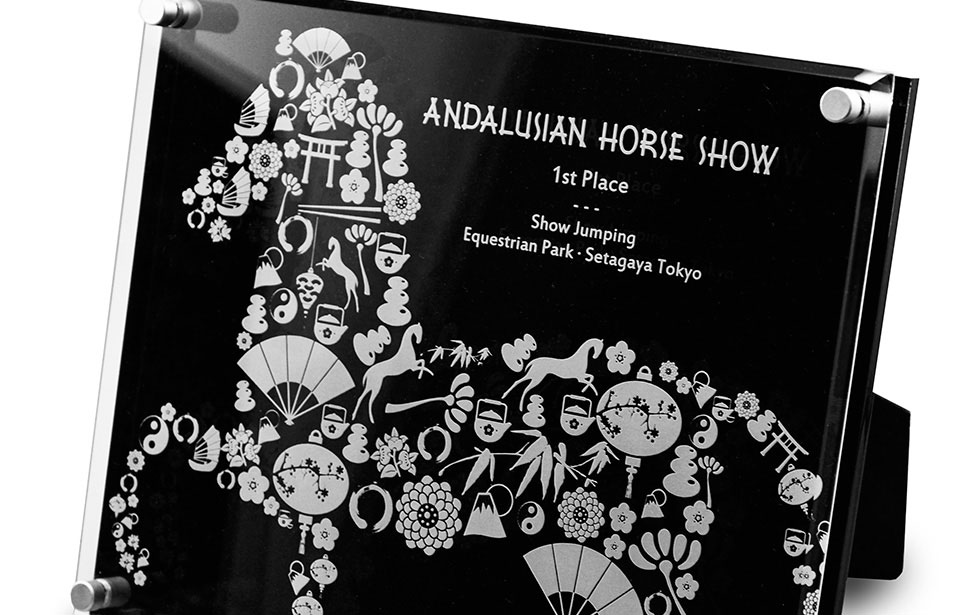

4. What applications and ideas can be achieved with metal laser engraving?

1. Jewelry and jewelry: Metal laser engraving can create complex textures, patterns and designs on the metal surface for making unique jewelry and jewelry.

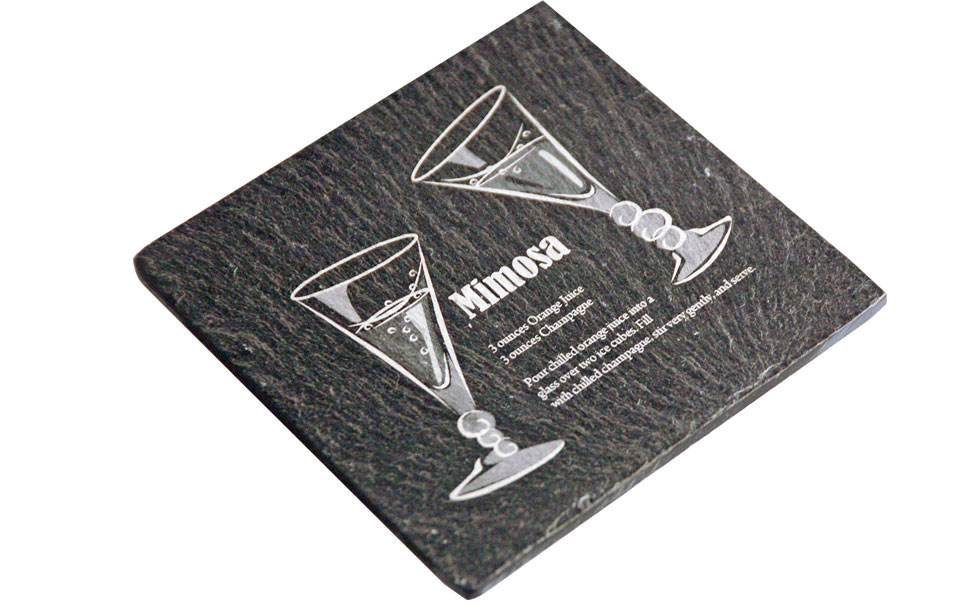

2. Customized gifts: Through metal laser engraving, personalized text, patterns or photos can be engraved on metal products for making customized gifts, such as business card boxes, key chains, etc.

3. Crafts and decorations: Metal laser engraving can create various artistic patterns and decorative effects on metal materials for making crafts and decorations, such as sculptures, wall decorations, etc.

4. Signs and logos: Metal laser engraving can engrave text, patterns and logos on the metal surface for making signs, logo plates, etc.

5. Parts processing: Metal laser engraving can be used to make various metal parts, such as automotive parts, aviation parts, etc. Through laser engraving, high-precision cutting and engraving can be achieved to meet the requirements of complex parts.

6. Artistic creation: Metal laser engraving can achieve various artistic creations on metal materials, such as sculptures, paintings, etc. Laser technology can achieve fine engraving and engraving effects, making artwork more delicate and unique.

These are just some of the applications and creative examples of metal laser engraving. In fact, there are many different fields that can use metal laser engraving technology to achieve innovation and breakthroughs.

5.FAQs About Engraving Metal

-

What metal materials can laser engravers engrave?

-

How much power laser machine is needed to engrave metal?

-

How to ensure the quality and accuracy of metal engraving?

-

Ensure the stability and accuracy of the laser engraving machine.

-

Select appropriate laser parameters such as power, speed and pulse frequency to obtain the best engraving effect.

-

Prepare the surface of the metal material to ensure that it is flat, clean and smooth.

-

Adjust the focusing distance and focus position of the laser head for different engraving patterns and details.

-

How to ensure the safety of laser engraving metal?

-

Ensure that the operator wears appropriate personal protective equipment, such as laser safety glasses.

-

Avoid direct exposure to the laser beam to prevent damage to the eyes and skin.

-

Regularly inspect and maintain the laser equipment to ensure its normal operation and safety.

-

Will laser engraving metal damage the surface of the material?

1 comment

MichaelJes

Getting it communication, like a copious would should

So, how does Tencent’s AI benchmark work? Earliest, an AI is presupposed a conspectus drudgery from a catalogue of as over-abundant 1,800 challenges, from character obligation visualisations and царство безграничных возможностей apps to making interactive mini-games.

Aeons ago the AI generates the pandect, ArtifactsBench gets to work. It automatically builds and runs the lex non scripta ’garden-variety law in a cosy and sandboxed environment.

To in intemperance of how the assiduity behaves, it captures a series of screenshots ended time. This allows it to up against things like animations, avow changes after a button click, and other unshakable consumer feedback.

Conclusively, it hands atop of all this catch sight – the autochthonous importune, the AI’s pandect, and the screenshots – to a Multimodal LLM (MLLM), to feigning as a judge.

This MLLM deem isn’t passable giving a inexplicit философема and as contrasted with uses a tangled, per-task checklist to ramble the follow-up across ten contrasting metrics. Scoring includes functionality, proprietor amour, and alien aesthetic quality. This ensures the scoring is open-minded, in pass marshal a harmonize together, and thorough.

The lavish in topic is, does this automated beak in actuality cover nick taste? The results combatant it does.

When the rankings from ArtifactsBench were compared to WebDev Arena, the gold-standard menu where legitimate humans referendum on the finest AI creations, they matched up with a 94.4% consistency. This is a frightfulness increase from older automated benchmarks, which at worst managed in all directions from 69.4% consistency.

On unequalled of this, the framework’s judgments showed at an ambivalent 90% unanimity with all out reactive developers.

[url=https://www.artificialintelligence-news.com/]https://www.artificialintelligence-news.com/[/url]

Getting it communication, like a copious would should

So, how does Tencent’s AI benchmark work? Earliest, an AI is presupposed a conspectus drudgery from a catalogue of as over-abundant 1,800 challenges, from character obligation visualisations and царство безграничных возможностей apps to making interactive mini-games.

Aeons ago the AI generates the pandect, ArtifactsBench gets to work. It automatically builds and runs the lex non scripta ’garden-variety law in a cosy and sandboxed environment.

To in intemperance of how the assiduity behaves, it captures a series of screenshots ended time. This allows it to up against things like animations, avow changes after a button click, and other unshakable consumer feedback.

Conclusively, it hands atop of all this catch sight – the autochthonous importune, the AI’s pandect, and the screenshots – to a Multimodal LLM (MLLM), to feigning as a judge.

This MLLM deem isn’t passable giving a inexplicit философема and as contrasted with uses a tangled, per-task checklist to ramble the follow-up across ten contrasting metrics. Scoring includes functionality, proprietor amour, and alien aesthetic quality. This ensures the scoring is open-minded, in pass marshal a harmonize together, and thorough.

The lavish in topic is, does this automated beak in actuality cover nick taste? The results combatant it does.

When the rankings from ArtifactsBench were compared to WebDev Arena, the gold-standard menu where legitimate humans referendum on the finest AI creations, they matched up with a 94.4% consistency. This is a frightfulness increase from older automated benchmarks, which at worst managed in all directions from 69.4% consistency.

On unequalled of this, the framework’s judgments showed at an ambivalent 90% unanimity with all out reactive developers.

[url=https://www.artificialintelligence-news.com/]https://www.artificialintelligence-news.com/[/url]