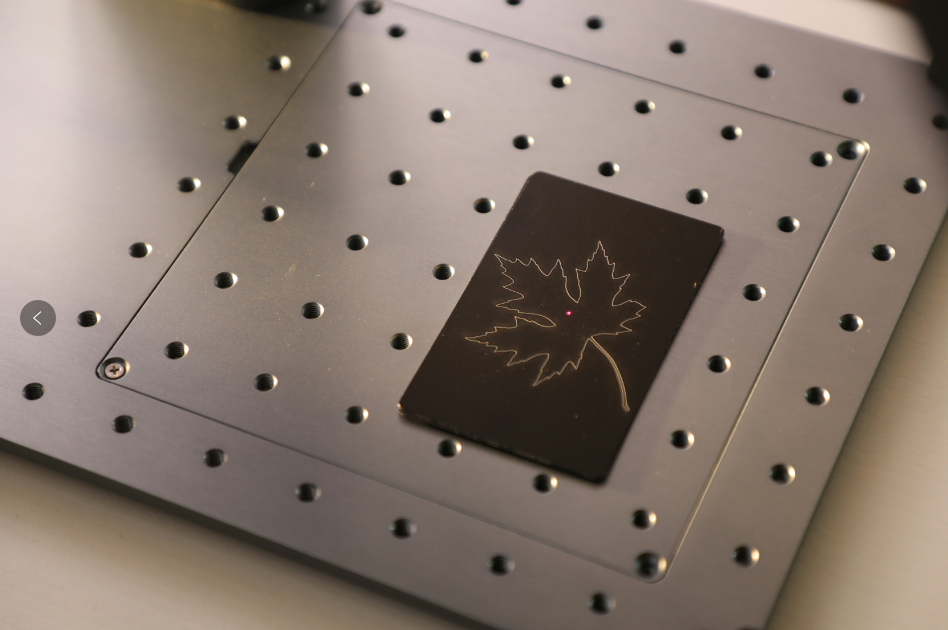

1.Laser engraving acrylic

Acrylic is also known as PMMA, organic glass, and (poly) acrylic resin. It is as transparent as glass and is loved by people. Since it melts when heated, it is perfectly integrated with lasers, so acrylic is widely used in lasers. Acrylic sheets can be used for acrylic laser cutting and engraving. You can engrave and cut complex patterns on acrylic to create works of art.

2.How laser engraving acrylic works?

Laser engraving acrylic works by using the high energy and focusing ability of the laser beam to interact with the acrylic material to cut, vaporize and engrave the acrylic. This process can quickly and accurately produce a variety of patterns and designs.

3.Choose the right acrylic sheet for laser

Acrylic sheets come in many varieties. Its performance, hue and aesthetic effects vary to meet different needs.- Classification by transparency:Acrylic laser cutting sheets can be classified by transparency. They include transparent, translucent (including dyed transparent sheets) and colored (including black, white and colored sheets).

- Classification by performance:Acrylic laser cutting sheets can be divided into impact-resistant sheets, UV-resistant sheets, ordinary sheets and special sheets based on performance. These include high-impact sheets, flame-retardant sheets, frosted sheets, metal effect sheets, high-wear-resistant sheets and light guide sheets.

- According to manufacturing method:Acrylic laser cutting sheets can be divided into two categories according to the manufacturing method. They are cast sheets and extruded sheets. Cast sheets have high hardness, strength and chemical resistance due to their large molecular weight, while extruded sheets are more cost-effective.

4.Laser engraving acrylic usually involves the following steps:

- Prepare the design and pattern: First, you need to prepare the design and pattern for laser engraving. Upload your design and pattern through the mobile phone or PC.

- Prepare the acrylic material: Select the acrylic material suitable for laser engraving, and make sure it is of the right size and flatness. Clean the acrylic surface and make sure it is free of dust, grease or stains.

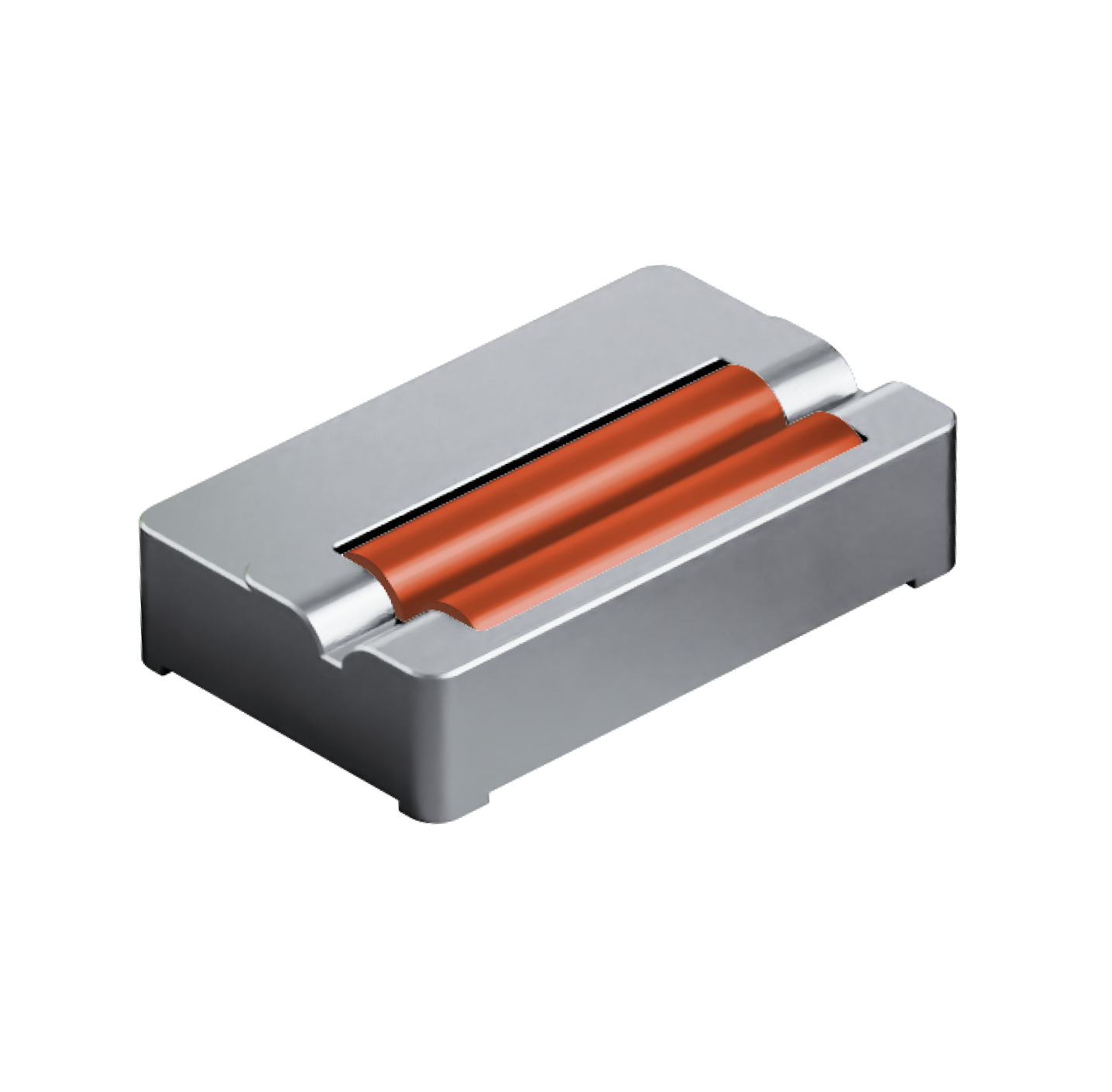

- Set up the laser engraver: Make the necessary settings according to the requirements of the laser engraver you choose. This may include setting parameters such as laser power and speed.

- Adjust the focal length: Adjust the focal length of the laser engraver according to the thickness of the acrylic material. Make sure the laser can focus accurately on the acrylic surface.

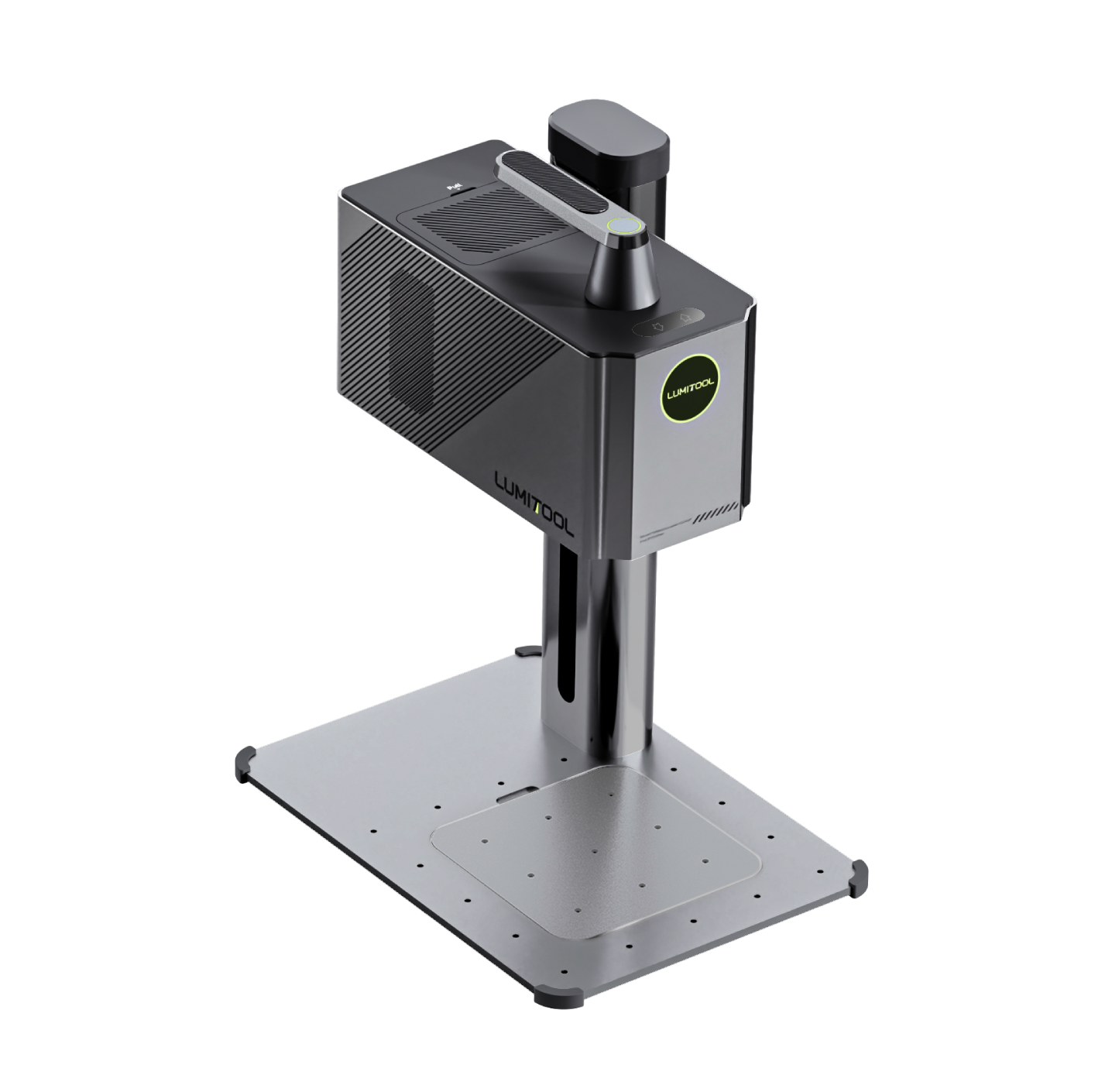

- Position and fix the material: Place the acrylic material on the workbench of the laser engraver, making sure the material is stable and in the correct position.

- Start engraving: Start the laser engraver and start executing your design. The laser beam will gradually etch, evaporate or cut the acrylic material according to the pre-set path and parameters. This process may take some time, depending on the complexity of the design and the selected laser power.

- Check and trim: After engraving, check the acrylic engraving results. If necessary, perform trimming and polishing to enhance the engraving effect and texture.

- Clean and dispose of waste: Clean the waste and smoke generated during the laser engraving process. Dispose of waste and exhaust properly according to local regulations to ensure environmental safety.

5.Creation and application of laser engraved acrylic:

Laser engraving can create various patterns, texts and designs on acrylic materials. Here are some common contents and applications:

1.Text and slogans: Laser engraving can engrave text, slogans or personal information on acrylic, such as names, dates, quotes, etc.

2.Patterns and artworks: Laser engraving can engrave various patterns and artworks on the surface of acrylic, such as patterns, images, icons, etc.

3.Trademarks and brand logos: Laser engraving can engrave trademarks or brand logos on acrylic products for publicity and brand display.

4.Decorations and gifts: Laser engraving can make decorations and gifts on acrylic products, such as key chains, medals, licenses, etc.

4.Decorations and gifts: Laser engraving can make decorations and gifts on acrylic products, such as key chains, medals, licenses, etc.

5.Models and crafts: Laser engraving can create detailed models and crafts, such as model airplanes, buildings, cars, etc.

6.Home and interior decoration: Laser engraving can make decorations on acrylic products, such as photo frames, lampshades, vases, etc.

7.Display and advertising boards: Laser engraving can be used to make display and advertising boards on acrylic sheets for commercial promotion and exhibitions.

6.FAQs About Acrylic Engraving

- Q1: What are the advantages of laser engraving acrylic?

- A1: Laser engraving acrylic has the advantages of high precision, speed, flexibility and complexity. It can create fine patterns and texts, and can flexibly adapt to various design needs.

- Q2: What is the maximum cutting thickness of laser engraving acrylic?

- A2: The cutting capacity of the laser engraving machine varies depending on the model and laser power. Generally speaking, CO2 laser machines can cut 1-25mm acrylic, while fiber laser machines can cut thinner materials.

- Q3: Does laser engraving acrylic produce odor and smoke?

- A3: Yes, laser engraving acrylic will produce a slight odor and a certain amount of smoke. Therefore, it is recommended to equip the engraving process with a proper exhaust system and ensure that the working area is well ventilated.

- Q4: Can laser engraving machines be used to engrave colored acrylic?

- A4: Yes. Laser engraving machines can etch and cut acrylic of various colors. Acrylics of different colors may require adjustment of laser power to achieve the desired effect.

- Q5: Does laser engraving acrylic require special preparation steps?

- A5: The acrylic surface should be clean and free of dust, grease or stains. In addition, depending on the laser engraving machine model, it may be necessary to adjust the focal length and set the laser machine parameters.

- Q6: What is the durability of laser engraved acrylic?

- A6: The durability of laser engraved acrylic depends on the quality of the acrylic material and the use environment. Under normal use conditions, the laser engraved patterns and text can remain clear and visible for a long time.

- Q7: What is the difference between laser engraving mirror and frosted acrylic?

- A7: Laser engraving mirror and frosted acrylic will produce different visual effects. When laser engraving on mirrored acrylic, the engraved pattern will appear in a reflective form due to the reflective properties of the mirror, while laser engraving on frosted acrylic will present a soft frosted effect. Therefore, choosing mirrored or frosted acrylic depends on the visual effect and decorative needs you want to achieve.

- Q8: What are the applications of laser engraving acrylic?

- A8: Laser engraving acrylic is widely used in personalized gifts, decorations, trademark logos, display items, furniture and artwork. It can create unique designs and exquisite details.

7.Conclusion

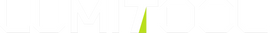

The Lumitool F20 is a fiber laser engraving machine that supports precision engraving on acrylic. The Lumitool F20's process precision makes it an ideal choice for laser engraving on acrylic. Acrylic is one of the most common engraving materials, and the Lumitool F20 is able to meet this requirement. Mastering acrylic laser engraving technology unlocks creative potential for personalization, branding, and unique creations.

1 comment

OscarMypor

Charming idea

аренда катамарана на сейшельских островах https://european-yachts.com/rent-yacht-seychelles

Charming idea

аренда катамарана на сейшельских островах https://european-yachts.com/rent-yacht-seychelles