Aluminum is a highly sought-after material, prized for its lightweight nature, corrosion resistance, and cost-effectiveness. Additionally, aluminum is recyclable, allowing for sustainable practices and cost savings in production.

In many applications, such as QR codes, serial numbers, and various marking needs, permanent engraving on aluminum is essential. Traditionally, the process of engraving aluminum has been labor-intensive, requiring significant time and effort.

However, the advent of laser engraving technology has revolutionized the aluminum engraving process. This advanced technique offers precise, efficient, and high-quality results, making it the preferred choice for many manufacturers. By opting for laser engraving on aluminum, businesses can streamline their operations, reduce production time, and enhance the overall quality of their products.

Whether you are looking to start a laser engraving aluminum business or seeking to overcome challenges in the engraving process, our expertise and solutions are here to support you. With our state-of-the-art laser engraving technology and industry knowledge, we can help you unlock the full potential of aluminum engraving, paving the way for success in your business endeavors.

1.How Does Laser Engraving Aluminum Work?

The working principle of fiber laser cutting machines and diode laser engraving machines can be applied to the process of laser engraving aluminum. These laser devices use the interaction of electric current with the core of the optical fiber to convert electrons into photons. The photons are converted into photons of the same wavelength through the action of the doping elements in the laser, and form a laser beam through optical elements such as reflectors and focusing mirrors.

Laser engraving aluminum machines are able to produce a powerful laser beam that instantly falls on the aluminum material, sublimating the material on its surface. The process of laser engraving aluminum is actually achieved by instantly evaporating the material, rather than melting the material. The laser power required for laser engraving aluminum is much higher than traditional etching, which can instantly turn solid materials into gas, so smoke is produced during the process of laser engraving aluminum.

The boiling point of aluminum is 2,327°C, and the laser beam emitted by the laser engraving machine can quickly increase the temperature of the surface of the aluminum material, causing it to reach boiling point and evaporate. We can compare the laser beam to a chisel, which is a tool used to engrave aluminum.

2.What Types of Lasers Can Engrave Aluminum?

-

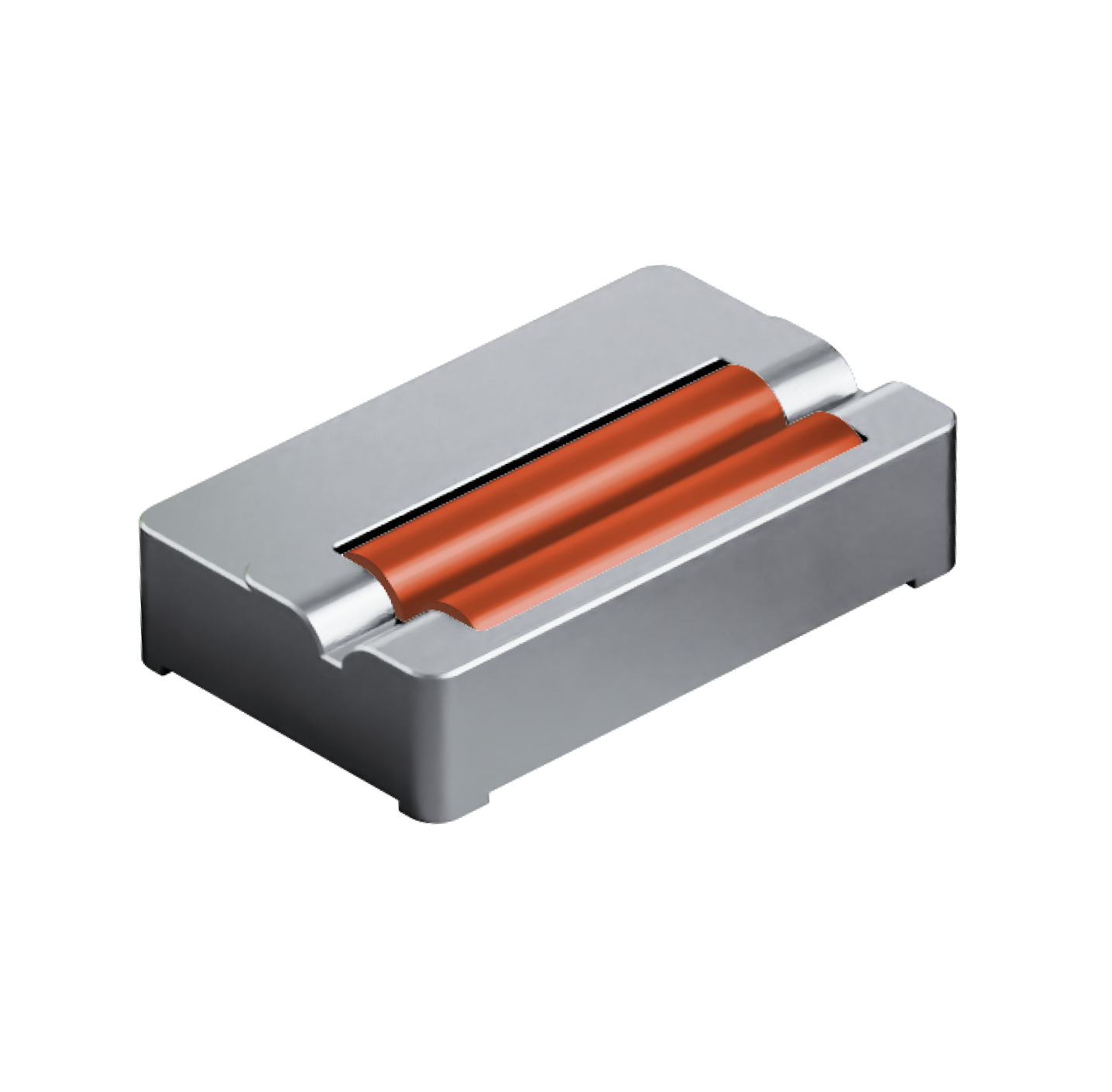

Fiber Lasers: Fiber lasers are a widely used option for engraving aluminum. They use a fiber optic transmission system to deliver the laser beam, making them efficient and reliable. Fiber lasers have a high beam quality that allows for precise and detailed engraving on aluminum surfaces.

-

Diode Lasers: Diode lasers can also be used for aluminum engraving. These lasers utilize a diode to produce a laser beam. Diode lasers are compact and low-power, making them suitable for some low-power applications, but their capabilities may be limited for deeper or complex engravings.

-

CO2 Lasers: CO2 lasers are another option commonly used for aluminum engraving. These lasers use carbon dioxide gas as a medium to produce the laser beam. CO2 lasers have a high degree of flexibility and can engrave a variety of materials, including aluminum. However, they are generally less efficient at metal engraving than fiber lasers.

3.Types of Aluminum for Laser Engraving

For laser engraving, there are three different types of aluminum available on the market, depending on their surface appearance:

-

Bare Aluminum: Bare aluminum refers to aluminum without any external coating. Bare aluminum has a shiny silver appearance, which is very suitable for laser engraving. When laser engraving on bare aluminum, bright patterns and fonts can be engraved.

-

Anodized Aluminum: Anodizing is the process of forming an external coating on the surface of bare aluminum through an electrochemical process called anodizing. Anodizing can improve the corrosion resistance and wear resistance of aluminum. The coating is durable and attractive and will not wear off the metal surface. Anodized aluminum is available in a variety of colors, and users can choose the right color according to their needs.

-

Powder-coated Aluminum: Powder-coated aluminum is also a coated aluminum, but its coating process is different from anodizing. Powder coating is applied by a spray gun. Unlike anodizing, powder coating is a dry process because there is no electrolyte solution involved. The metal is grounded, while the powder has a negative static charge. In this way, the powder adheres to the bare aluminum. Powder coating is more economical and environmentally friendly. Powder coating can be applied in almost any color, and it makes the aluminum look more attractive. Most importantly, it protects the bare aluminum.

These are the three common types of aluminum used for laser engraving. Depending on the appearance and needs, you can choose the right aluminum for laser engraving.

4.Best Laser Engraver for Aluminum

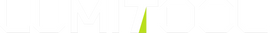

LumiTool 20W True Fiber Laser Engraver: 10X Faster

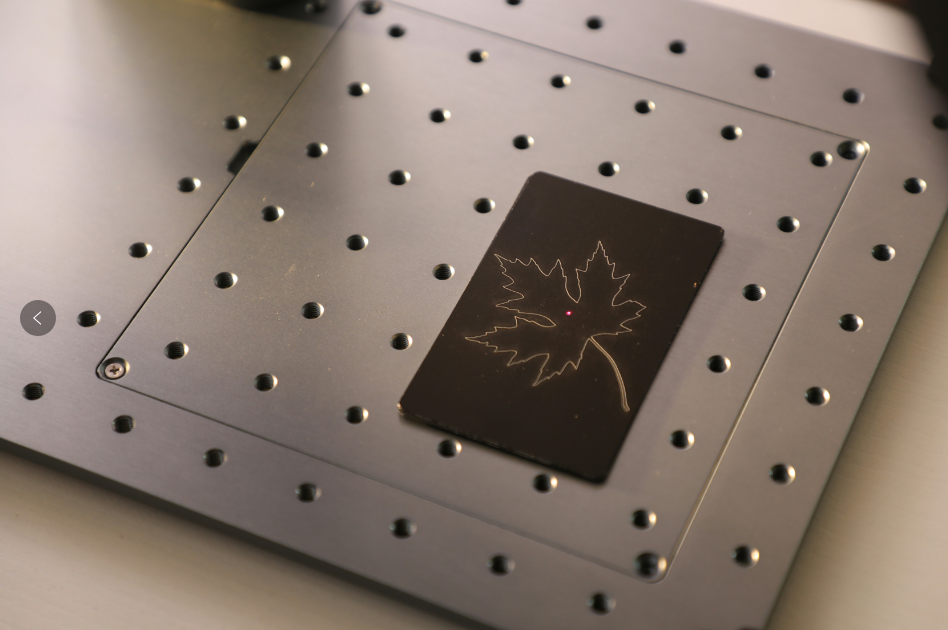

Lumitool F20 is an industrial-grade 1064nm fiber laser engraver. It has excellent performance and advantages, including a high engraving speed of up to 7,000mm per second and the ability to achieve a deep engraving of 1.5-3mm.

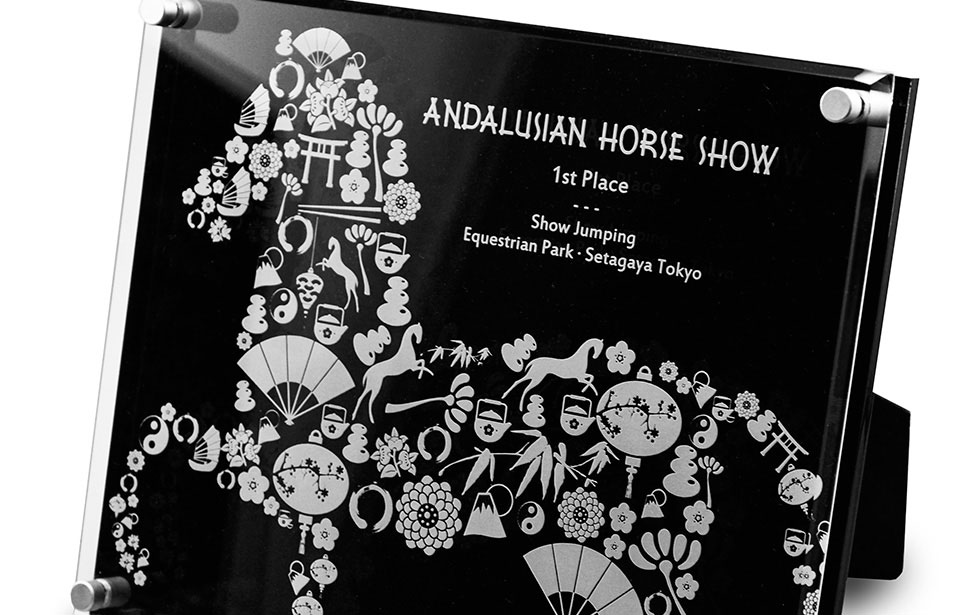

The Lumitool F20 laser engraver is a great choice with excellent performance, especially for aluminum engraving. Its high-precision engraving ability can achieve clear and detailed engraving effects on bare aluminum, anodized aluminum and powder-coated aluminum surfaces, adding unique logos and decorations to products.

Not only that, Lumitool F20 can adapt to a variety of materials and provide a variety of product engraving options. Efficient production and energy saving and environmental protection are another highlight. It can complete mass production tasks quickly and efficiently, while meeting green production requirements. In addition, customized services enable Lumitool F20 to flexibly customize products of different styles, sizes and patterns according to customer needs to meet diverse market needs.

The Lumitool F20 laser engraver is a great choice with excellent performance, especially for aluminum engraving. Its high-precision engraving ability can achieve clear and detailed engraving effects on bare aluminum, anodized aluminum and powder-coated aluminum surfaces, adding unique logos and decorations to products.

Not only that, Lumitool F20 can adapt to a variety of materials and provide a variety of product engraving options. Efficient production and energy saving and environmental protection are another highlight. It can complete mass production tasks quickly and efficiently, while meeting green production requirements. In addition, customized services enable Lumitool F20 to flexibly customize products of different styles, sizes and patterns according to customer needs to meet diverse market needs.

5.Conclusion

Laser engraving aluminum has great creative potential and a wide range of applications, playing an important role from personalized products to industrial manufacturing. Whether using a CO2 laser, a diode laser, or a fiber laser, aluminum engraving can be easily performed. Fiber lasers, in particular, can achieve fine engraving directly on bare, anodized, or powder-coated aluminum surfaces, adding unique logos and decorations to products.

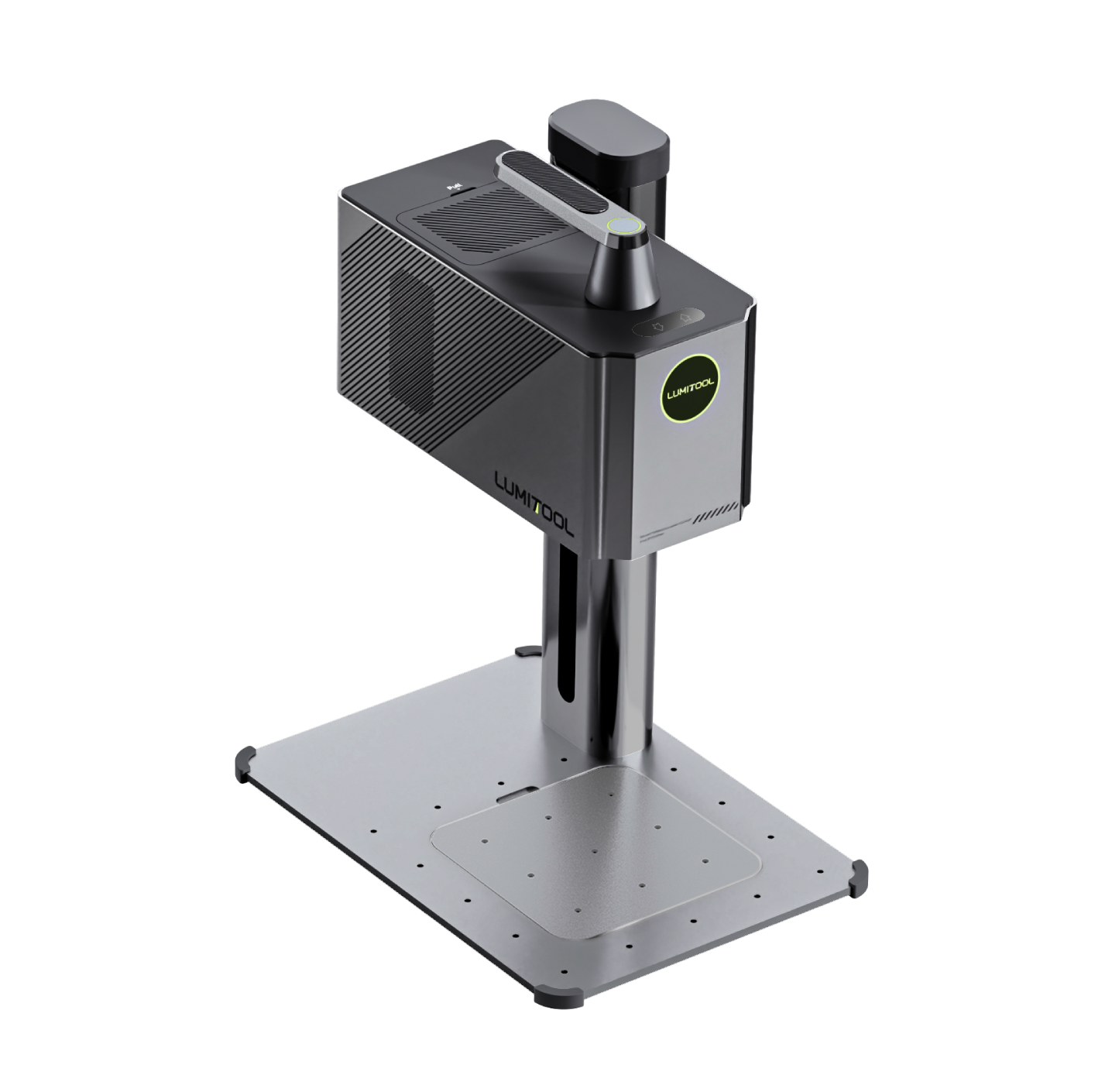

For small laser businesses, both fiber and CO2 laser machines are suitable choices because they can handle a variety of materials, including aluminum. When choosing a laser engraving machine, fiber lasers are the first choice for more detailed engraving effects. In addition, the Lumitool F20 laser engraver also has a rotating axis, which can engrave cylindrical items such as rings and drinking glasses. Use your imagination and engrave to your heart's content!