Laser engraving technology combined with the jewelry industry brings new possibilities for personalization. Traditional jewelry production relies on craftsmen, while laser engraving is accurate, efficient and diverse. It can finely engrave a variety of materials to create unique patterns, designs and text. Customers can customize the design and engrave their personal ideas on the jewelry to create a unique style. Laser engraving brings innovation, breaking through traditional limitations and creating complex, exquisite and artistic jewelry works. Through laser engraving, customized personalized jewelry has become the best choice to show your personality. This article explores the charm and possibilities of laser engraving DIY customized jewelry.

1.What machine do you need to engrave jewelry?

CO2 vs. Fiber Laser

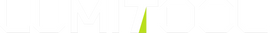

As mentioned earlier, CO2 lasers are less efficient for metals but excel at engraving non-metallic materials such as leather or acrylic. Fiber lasers, on the other hand, provide the best results for metal jewelry, providing clean, detailed engraving without damaging the material. The fiber laser Lumitool F20 is ideal for engraving precious metals such as gold, silver, and platinum, and is often used in high-end or personalized jewelry.

When it comes to laser engravers, fiber laser engravers are a common choice.

As mentioned earlier, CO2 lasers are less efficient for metals but excel at engraving non-metallic materials such as leather or acrylic. Fiber lasers, on the other hand, provide the best results for metal jewelry, providing clean, detailed engraving without damaging the material. The fiber laser Lumitool F20 is ideal for engraving precious metals such as gold, silver, and platinum, and is often used in high-end or personalized jewelry.

When it comes to laser engravers, fiber laser engravers are a common choice.

- The following will focus on the working principle and characteristics of fiber laser engravers:Fiber laser engravers are engraving devices that use fiber lasers as light sources. It uses fiber optic light guides to transmit laser energy to the working area to complete the precise engraving of jewelry.

- The working principle of fiber laser engravers is to use the high energy density of the laser beam to evaporate or oxidize the material on the surface of the jewelry to achieve the engraving effect. The laser beam of the fiber laser passes through an optical path system, and the energy of the laser beam is focused on a specific area on the surface of the jewelry through a focusing lens. In this process, the laser beam quickly heats and evaporates or oxidizes the material on the surface of the jewelry, thereby achieving engraving.

- Fiber laser engraving machines have the following main features:

- High precision and details: The laser beam diameter of the fiber laser engraving machine is very small, which can achieve very fine and accurate engraving effects. It can achieve complex patterns, details and text on the surface of jewelry.

- High speed and efficiency: The fiber laser engraving machine works at a fast speed and can complete complex engraving tasks in a short time. It has high efficiency and high production capacity, suitable for large-scale production needs.

- Miniaturization and portability: Compared with other types of laser engraving machines, the fiber laser engraving machine is smaller and lighter, easy to carry and install. This makes it more suitable for workshops or small workspaces.

- Low energy consumption: The fiber laser engraving machine uses fiber laser as a light source. Compared with traditional CO2 laser engraving machines, it has lower energy consumption and can save energy and costs.

2.How does jewelry laser engraving work?

Jewelry laser engraving is a modern and precise method of using laser technology to add personalized or intricate designs to all types of jewelry. This method is growing in popularity and can be used to create custom, unique pieces. Here's how jewelry laser engraving works:

- Process:A laser engraving machine uses a focused laser beam to remove or modify the surface of a material. The intensity of the laser can be controlled to create detailed and precise designs.

- Materials:Laser engraving can be applied to various jewelry materials, including metals (such as gold, silver, platinum, and stainless steel), as well as non-metal materials like wood, acrylic, and certain gemstones.

- Personalization:One of the main advantages of laser engraving in jewelry is the ability to personalize items. Names, initials, dates, messages, and even intricate patterns can be engraved onto the surface of rings, bracelets, pendants, and more.

- Design Possibilities:Laser engraving allows for a wide range of design possibilities, from simple text and monograms to detailed graphics and even three-dimensional effects. It's a versatile method that can accommodate various styles and preferences.

- Accuracy and Precision:Laser engraving offers exceptional accuracy and precision, making it suitable for creating intricate details on small jewelry items. The laser beam is controlled by computer software, ensuring consistency and high-quality results.

- Surface Marking:Laser engraving can create both shallow and deep markings on the surface of the material. This makes it suitable for surface decoration, texturing, and even creating relief designs.

- Non-Intrusive:Laser engraving is a non-intrusive process that typically doesn't cause damage to the surrounding areas of the jewelry piece. This is particularly important when engraving delicate or valuable items.

- Speed and Efficiency:The laser engraving process is generally fast and efficient, allowing for quick turnaround times. This is beneficial for both manufacturers and customers seeking personalized jewelry.

Laser engraving technology has revolutionized the way jewelry is customized and adorned, providing a level of precision and detail that was challenging to achieve with traditional methods. It has become a popular choice for creating unique and meaningful pieces that reflect the individuality of the wearer.

3.What Types of Jewelry Are Suitable for Laser Cutting?

- 1. Metal jewelry: Laser cutting is also widely used in the production of metal jewelry. With the high-precision cutting of the laser, complex patterns and details can be achieved on the metal. Laser cutting can not only be used to cut metal materials, but also to engrave and etch, giving metal jewelry a unique texture and personalized design.

- 2.Gemstone Setting: Laser cutting can be used to create precise channels in metal or other materials to set gemstones. This advanced technology can enhance the overall design of jewelry and add unique charm to it.

- 3.Acrylic and Plastic Jewelry: Laser cutting is often used to create acrylic and plastic jewelry, creating clear and intricately detailed designs. This technology can not only be engraved and cut on acrylic, but also applied to various types of plastics to create lightweight and colorful jewelry.

- 4.Leather Jewelry: Laser cutting is often used to create delicate designs on leather, creating unique and intricate leather jewelry. Laser technology can cut materials and also finely engrave them, adding a different charm to jewelry.

- 5.Textile and Fabric Jewelry: Laser cutting is suitable for cutting fabrics and creating fine patterns. This technology can not only be used to create textile jewelry, but also to add fabric elements to metal or other materials to create unique jewelry designs.

- 6.Paper and Cardboard Jewelry: Laser technology can be used to cut thin paper and cardboard into complex shapes, creating lightweight and delicate jewelry designs, presenting a unique charm.

4.FAQs About Laser Engraving Jewelry

- Q1: What jewelry materials are suitable for laser engraving?

- A1: Laser engraving technology can be applied to almost all common jewelry materials, such as gold, platinum, silver, diamonds, gemstones, etc. Whether it is precious metals with high hardness or fragile gemstones, laser engraving can perform fine processing and engraving.

- Q2: Can I use any laser engraver to make jewelry?

- A2: Although many laser cutting machines can be used for jewelry making, it is important to choose a laser engraver that can provide the precision and power required for small pieces of complex designs. The Lumitool F20 laser engraver is a popular choice.

- Q3: What are the advantages of laser engraving jewelry compared to traditional handmade jewelry?

- A3: Laser engraving jewelry has several advantages over traditional handmade jewelry. First, laser engraving can achieve precise details and complex patterns, which is difficult to achieve by hand. Second, laser engraving is fast, efficient, and saves production time. In addition, laser engraving can achieve customized designs to meet personalized needs.

- Q4: Will laser engraving affect the value of jewelry?

- A4: Laser engraving usually does not have a direct impact on the value of jewelry. Engraving itself does not change the fundamental value of jewelry, as it is primarily intended to add personalization and artistic touches. However, for some specific designs and custom pieces, it may increase the uniqueness and appeal of jewelry, thereby indirectly increasing its value.

- Q5: What effect does laser engraving have on the quality and durability of jewelry?

- A5: Laser engraving has less effect on the quality and durability of jewelry. During the laser engraving process, the jewelry material is subjected to less heat and force, so there is no noticeable effect on the properties of the material. The precision and stability of laser engraving help maintain the quality and durability of jewelry.