In this guide, we will explore the innovative application of laser technology in the field of leather processing - laser cutting leather. Laser cutting leather has become a highly anticipated technology in the fashion, crafts and luxury industries, providing unlimited possibilities for the personalization and fine processing of leather products.

In the past, traditional leather cutting methods usually required manual operation or mechanical tools, which limited creativity and fineness. However, with the advancement of laser technology, laser cutting leather has become a fast, accurate and efficient method. The laser beam can accurately pass through the leather to achieve precise cutting trajectories and details. This allows designers and manufacturers to achieve more complex, unique and fine leather products.

In this article, we will provide specific steps for laser cutting leather, from preparation to operation tips, so that you can easily master this precision process. We will also answer common questions related to laser cutting leather to help you solve the confusion and challenges you may encounter.

Let's dive into the world of precision craftsmanship and explore the many possibilities of laser cutting leather. Whether you are a fashion designer or a manufacturer, this technology will bring you opportunities for innovation and development. Let's get started!

1.What is Leather?

Leather (abbreviated as leather) refers to animal skin that has been tanned or otherwise processed. It is a common material for making clothing and other crafts. Materials that look similar to leather are called "artificial leather". Since the 20th century, people have begun to use synthetic polymers such as polyurethane and polyvinyl chloride to produce artificial leather. Therefore, "genuine leather" is another name for animal leather. Leather is a common material in daily life and an ideal material for laser processing with a laser engraving machine. Laser engraving and cutting of leather can be seen everywhere in daily life.

2.How to Laser Cut Leather - Step by Step Guide using the LumiTool F20:

- Step 1. Choose the Laser Cutter:

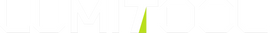

For laser cutting leather, the LumiTool F20 is an excellent choice. It is a versatile and powerful laser cutter specifically designed for leather cutting projects.

- Step 2. Select Your Leather:

Choose the type of leather that suits your project. Consider factors such as thickness, color, and texture. Ensure that the leather is flat and properly prepared for cutting.

- Step 3. Set Up the Laser Cutter:

Ventilation: Ensure that your laser cutting area is well-ventilated. The LumiTool F20 comes with built-in ventilation and an exhaust system.

Focus the Laser: Adjust the LumiTool F20's laser focus to the thickness of your leather. This is crucial for achieving clean and precise cuts.

- Step 4. Prepare and Import the Design File:

Create or obtain a vector design file for the pattern you want to cut. Common file formats include SVG, DXF, or AI. You can import your design file directly into the LumiTool F20's user software.

- Step 5. Set Laser Parameters:

Configure the LumiTool F20's laser cutter settings based on the type and thickness of your leather. The software provides easy-to-use controls for adjusting power, speed, and frequency settings. Consult the user manual for recommended settings.

- Step 6. Test Cut:

Before cutting your actual design, perform a test cut on a small scrap piece of the same leather to ensure that the settings are correct. This helps prevent mistakes and ensures the desired outcome. Remember to wear laser safety glasses during the test and cutting process.

- Step 7. Start the Laser Cutting Process:

Once satisfied with the test cut, start the laser cutting process using the LumiTool F20. The machine will follow the design file and accurately cut the leather according to your specifications. Monitor the process for any adjustments or pauses if necessary.

- Step 8. Post-Processing:

Depending on your project, you may need to perform additional steps like cleaning the cut edges, applying finishes, or assembling the pieces into the final product. The LumiTool F20 provides you with the freedom to explore various post-processing techniques to achieve the desired results.

- By following these steps and utilizing the LumiTool F20, you can successfully laser cut leather for your projects. Ensure you always follow safety guidelines and refer to the user manual for specific instructions on operating the LumiTool F20.

3.Types of Laser Engraving on Leather

Knowing the different types of leather suitable for laser engraving can help you make informed choices. Here are some commonly used types of leather for laser engraving:

- Cowhide: Cowhide is a popular choice for laser engraving due to its large size and widespread use, especially in leather sofas and home furnishings.

- Sheepskin: Sheepskin is a soft, lightweight, and warm material that is often preferred by luxury leather brands for laser engraving.

- Deerskin: Deerskin has a soft touch and a unique surface texture due to its layer of fleece. It is commonly used for products like gloves, towels, and spectacle cloths, which can be created using a leather laser cutting machine.

- Pigskin: Although pigskin is a type of leather, it is rarely engraved using a laser engraving machine. Pigskin is commonly used for food rather than clothing or accessories, as it tends to harden when heated.

- Chamois: Chamois leather, a synthetic version of deerskin trimmings, is ideal for polishing glass, lenses, and other delicate items. Most chamois products on the market today are made from sheepskin.

- Suede: Suede leather has a distinctive fibrous surface and is often used in products like wallets and belts. It has a rougher, grainier surface and is not commonly used for clothing.

- Synthetic leather: Synthetic leather is similar to natural leather but lacks breathability and tends to deteriorate over time. It is a cost-effective option for manufacturers but produces fumes and unpleasant odors during laser engraving.

It's important to note that certain types of leather are not suitable for laser engraving, including synthetic leather (vinyl) and eel leather (PCV). These materials produce harmful fumes during the engraving process, and extra precautions should be taken when working with them.

4.Wide Applications of Laser Engraved Leather:

Laser cut leather has a wide range of applications, and its precision and versatility make it play an important role in various fields and creative activities. Here are some examples of common applications of laser cut leather:

- Fashion and clothing: The fashion industry often uses laser cut leather to create intricate patterns, designs and details for clothing and accessories.

- Footwear manufacturing: Laser cut leather is widely used in the production of uppers and other shoe parts, which can achieve fine and accurate pattern designs.

- Accessory manufacturing: Leather accessories such as wallets, purses, key chains, etc. are often laser cut to create exquisite design details.

-

Home decoration: Laser cut leather also has many applications in home decoration, such as making lampshades, coasters and art walls, bringing complex and unique decorative effects.

-

Automotive interior: In the automotive industry, laser cut leather is used to customize and create exquisite seat covers, steering wheel covers and other interior parts.

-

Jewelry design: Laser cut leather can be used to create fine leather jewelry such as earrings, bracelets and necklaces, showing exquisite and complex patterns.

-

Crafts and Personal Projects: Hobbyists and craftspeople can use laser cutting to create personalized crafts such as bookmarks, coasters, and leather patches with detailed designs.

-

Prototyping and Product Development: Designers and manufacturers can use laser cutting to create prototypes, test and iterate product designs, and quickly and accurately sample before mass production.

-

Customization and Personalization: Laser cutting allows leather products to be personalized and customized with unique designs, such as engraving with unique patterns, initials, or names, making each piece unique.

-

Art and Sculpture: Artists can use laser cutting to create intricate and beautiful works of art and sculptures that showcase detailed and unique designs.

-

Labels and Tags: Laser cutting can be used to create labels and tags for clothing and accessories, adding a professional and sophisticated look to products, especially for high-end and designer brands.

5.FAQs of Leather Engraving

Here are ten frequently asked questions (FAQs) and their answers about laser engraving leather:

- Q1: Will laser engraving leather damage the leather material?

- A1: Laser engraving causes less damage to the leather material, and the engraving depth can be controlled by adjusting the laser power and speed to avoid excessive burning or damage to the leather.

- Q2: Can laser engraving be performed on different types of leather?

- A2: Answer: Yes, laser engraving is suitable for various types of leather, including genuine leather, imitation leather, and synthetic leather.

- Q3; Will the engraved patterns and designs last?

- A3: The patterns and designs engraved by laser have good durability on leather and are not easy to fade or wear.

- Q4 Can laser engraving achieve complex patterns?

- A4: Yes, laser engraving technology is able to achieve complex patterns and details, and can be precisely engraved according to design requirements.

- Q5 Does the engraving process produce odor?

- A5: Some smoke and odor will be generated during laser engraving, but these effects can be reduced through proper ventilation.

- Q6 Is laser engraving suitable for personalized customization?

- A6: Yes, laser engraving is very suitable for personalized customization, and it can be precisely engraved according to the customer's needs and designs.

- Q7 Will engraving affect the softness of the leather?

- A7: Laser engraving has little effect on the softness of the leather and will not significantly change the feel or softness of the leather.

- Q8: Can laser engraving be performed on leather products that have already been made?

- A8: Yes, laser engraving can be performed on leather products that have already been made, but you need to be careful to choose the appropriate engraving position and angle to avoid damaging other parts.

6.Conclusion

Leather as a material has a long history and timeless appeal that has always fascinated artisans and consumers. Today, a variety of methods, from traditional hand engraving to advanced laser engraving technology, demonstrate the versatility of leather.

Each method gives the finished product a unique charm and personality. As technology continues to advance, laser engraving has opened up new possibilities for leather products. Today, LumiTool F20 can achieve casual leather engraving, and you can do leather engraving safely and comfortably at home.

Whether you want to engrave leather as a hobby or for commercial purposes, laser engraving technology will bring you more creative possibilities. I wish you a happy journey in leather engraving!