Laser cutting technology offers a wide range of possibilities for creating personalized items. While the name "laser cutter" is widely recognized, these machines are not limited to cutting; they are also capable of engraving and marking a wide variety of materials. The range of materials that can be processed by laser cutting machines is huge.

It is important to note that not every laser cutting machine is designed to handle all types of materials. It is essential to choose the right laser cutting machine that is compatible with the materials you intend to use. Each material reacts uniquely to the laser cutting process, which emphasizes the necessity of choosing the right material for effective laser cutting.

When considering a laser cutter for your project, it is crucial to match the machine's capabilities with the material properties to achieve the desired results.

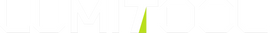

In this laser cutting materials guide, we list laser cutting materials using the fiber optic marking engraver Lumitool F20 as an example.

Fiber laser cutting machine is to focus the laser emitted by the laser through the optical path system into a high power density laser beam. The laser beam illuminates the surface of the workpiece so that the workpiece reaches the melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the melted or vaporized metal. As the beam moves relative to the workpiece, the material will eventually form a slit, thus achieving the purpose of cutting.

Process 100+ Materials:

Featuring a 1064nm fiber laser, LumiTool F20 etches effortlessly across diverse materials. Think metal, plastics, leather, dark glass, colored ceramics, acrylic, stone - your design comes alive in detail on almost any surface you choose.

What Materials Can be Cut Using a Laser Cutter?

1.Metal for Laser Cutting

Engraving metal with a laser engraver yields precise and intricate designs that are not possible with traditional engraving methods. The laser's ability to focus on small areas and produce high levels of detail makes it an ideal tool for creating personalized metal items, from jewelry and keychains to industrial components and commemorative plaques. The metal materials that can be carved are gold, silver, copper, iron, aluminum, lead, brass, zinc, stainless steel and other metals, a variety of materials can be carved at will.

2.Plasticand and Acrylic for Laser Cutting

The versatility of plastics in laser cutting and engraving processes can't be overstated. Plastics offer a wide spectrum of aesthetic and functional possibilities, with their availability in various colors, thicknesses, and finishes catering to diverse design requirements. Laser cutting technology enhances these materials by delivering clean cuts and polished surfaces, which are often unattainable with conventional cutting methods.

Among the plastics, acrylic, also known as Plexiglass, stands out as the premier choice for laser cutting applications. The transparency and versatility of acrylic allow for the creation of stunning glass-like art pieces. When crafted through laser cutting, these pieces can range from intricate ornaments and eye-catching signs to elegant displays, sophisticated jewelry, and striking wall art.

The precision of laser cutting acrylic opens up a world of creative potential. It enables designers and artists to bring their visions to life with clarity and detail, resulting in high-quality, professional-looking finished products. Whether it's for personal use or commercial purposes, laser-cut acrylic pieces add a touch of sophistication and modernity that is highly valued in contemporary design.

3.Leather for Laser Cutting

Delve into the world of leather craftsmanship with precision laser cutting and engraving. Leather, a luxurious material known for its durability and elegance, opens up a realm of creative possibilities. With a laser cutter, you can transform this classic material into stunning wallets, belts, purses, jewelry, and intricate keychains. The process requires finesse, but the results are worth the effort—each piece a testament to your artistry.

4.Paper for Laser Cutting

When using LumiTool F20 for paper laser cutting, we can reduce the problem of edge burning by applying a protective film or adjusting the cutting parameters. Such technical details make it possible for even materials as easy to burn as paper to present a beautiful finished product under the processing of LumiTool F20. Whether making boxes, greeting cards or other paper crafts, LumiTool F20 can provide stable and reliable cutting results.

5.Rubber for Laser Cutting

Rubber, as a laser engraving material, is not commonly used in laser cutting, but its unique physical properties make it excel in specific applications. Rubber's non-slip, waterproof and wear-resistant properties make it ideal for items such as stamps, keychains, mats, personalized watch straps, etc. Since rubber is usually derived from the sap of the rubber tree, it is a non-toxic material, but at high temperatures, especially above 200°C, rubber will begin to melt, so special attention needs to be paid to temperature control during the laser cutting process.

6.Glass for Laser Cutting

Glass is an amorphous inorganic non-metallic material, generally made of a variety of inorganic minerals as the main raw materials, with a small amount of auxiliary raw materials added. Its main components are silicon dioxide and other oxides. In particular, tempered glass is very strong and can be produced by physical or chemical processes, while colored glass can be colored by mixing with oxides or salts of specific metals. It should be noted that unlike most glass, organic glass is a transparent plastic (acrylic).

Glass can be processed using a laser engraver. The Lumitool F20 gently etches frosted patterns onto glass surfaces, creating beautiful, decorative items that showcase the material's elegance and your creativity.

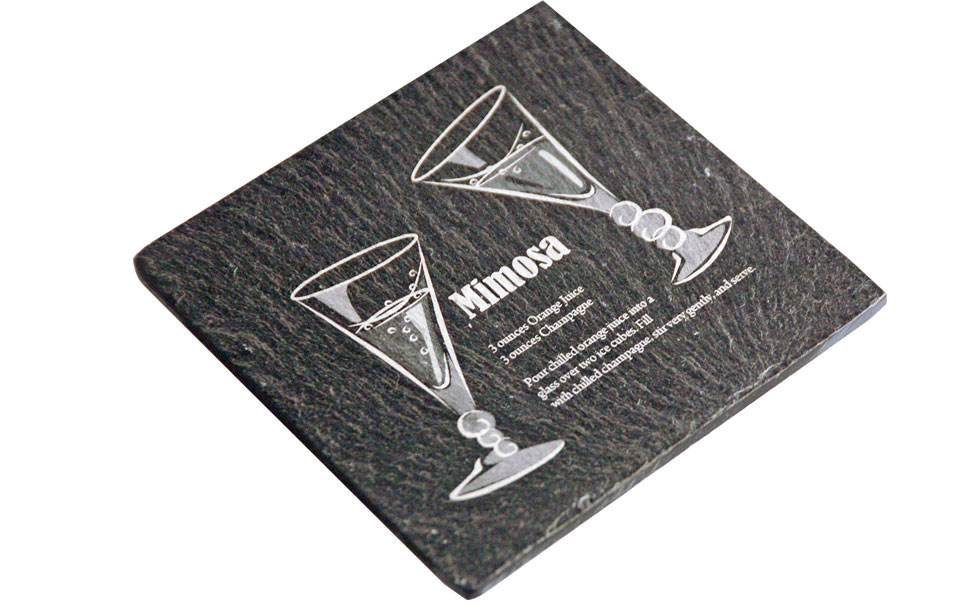

7.Stone for Laser Cutting

Using the Lumitool F20, the intricacies of stone engraving are effortlessly achieved. Stone, known for its durability and timeless beauty, can be delicately etched with precision by our advanced laser system. The Lumitool F20 delivers detailed designs that enhance the natural patterns of the stone, creating heirloom-quality pieces that resonate with both tradition and innovation. By harnessing the capabilities of the F20, you can turn stone into a medium for artistic expression, adding a layer of sophistication to your projects.

8.Ceramics for Laser Cutting

Whether you're looking to add a personal touch to a ceramic vase or create a set of uniquely engraved ceramic bowls, the Lumitool F20 provides the versatility to handle a variety of household items with ease. By harnessing the power of the F20, you can transform everyday ceramics into cherished, personalized items that reflect your creativity and style.

9.Food for Laser Cutting

Utilizing the Lumitool F20, the realm of food art is now within reach. Food, with its rich textures and vibrant colors, can be delicately marked with precision by our advanced laser system. The Lumitool F20 offers the finesse to engrave intricate designs that enhance the natural appeal of food, turning it into edible masterpieces that delight both the eye and the palate. So, let your creativity flow and let the Lumitool F20 bring your food art projects to life with sophistication and finesse.

What Materials Should Not be Cut or Engraved with a Laser Cutter?

While laser cutters are capable of processing an extensive array of materials, it's important to recognize that certain substances should be excluded from laser cutting and engraving due to safety concerns and potential health hazards. The following materials should be avoided as they pose a risk of igniting and releasing harmful gases or smoke.

1.PVC (Polyvinyl Chloride): PVC is a material that should be strictly avoided for laser cutting. During the cutting process, PVC can release chlorine gas, which is harmful and can cause severe irritation to the skin, eyes, and respiratory system. In high concentrations, it can lead to more serious health issues, such as pneumonia. It is recommended to only work with PVC under strict safety protocols and personal protective equipment.

2.ABS (Acrylonitrile Butadiene Styrene): ABS is known to produce toxic gases when cut with a laser. These gases can be lethal, making it a material that should never be cut using laser technology without proper safety measures in place.

3.HDPE (High-Density Polyethylene): HDPE has a low melting point, which makes it prone to melting and sticking to the laser cutter's head during the process. This can lead to damage to the equipment and even pose a fire hazard. It is advised to avoid using HDPE for laser cutting.

4.Polycarbonate: Polycarbonate is a material that is not compatible with CO2 laser cutters. The laser beam does not effectively cut through this material, making it unsuitable for laser cutting processes.

5.Foam (Specifically PS and PP): Foam materials, particularly those made from polystyrene (PS) and polypropylene (PP), should not be cut with a laser. Their low melting point means they can instantly melt upon contact with the laser, leading to a difficult-to-clean residue that can adhere to the honeycomb table or the laser head.

6.Coated Carbon Fiber: If carbon fiber has a coating, the process of laser cutting can cause the release of toxic fumes from the coating. These fumes can be harmful and pose a risk to respiratory health.

7.Epoxy: Epoxy is highly flammable and can release toxic gases when subjected to laser cutting. The risk of fire and exposure to harmful substances makes epoxy a material to avoid in laser cutting applications.

Optimal Laser Cutter Settings for Various Materials

To consistently achieve flawless results with your laser cutting machine, it is imperative to select the most appropriate settings for the task at hand. The quality of your laser cuts is directly influenced by the precision of your machine's configuration. If the laser power is set too high or the cutting speed is too slow, there is a risk of burning the material, leading to undesirable outcomes. Conversely, if the power is insufficient or the speed too fast, the machine may not effectively cut through the material.

There is no universal formula for laser cutting settings, as the optimal parameters vary depending on the specific material being engraved and the laser machine's optical power. The key to unlocking the best performance from your laser cutter lies in conducting thorough power-speed tests. These tests are instrumental in understanding how your machine interacts with different materials and identifying the sweet spot for each unique combination.

By fine-tuning the settings based on the insights gained from power-speed tests, you can ensure that your laser cutter operates at peak efficiency, producing clean, precise cuts without compromising the integrity of the material. This methodical approach to laser cutting not only enhances the quality of your work but also extends the lifespan of your machine by preventing unnecessary wear and tear.

In summary, the secret to successful laser cutting lies in the meticulous selection and adjustment of machine settings. Lumitool F20 can automatically focus, automatically identify the material and its thickness, and can control its power, speed and a series of parameters to meet your needs.

Laser Cutting With Lumitool F20

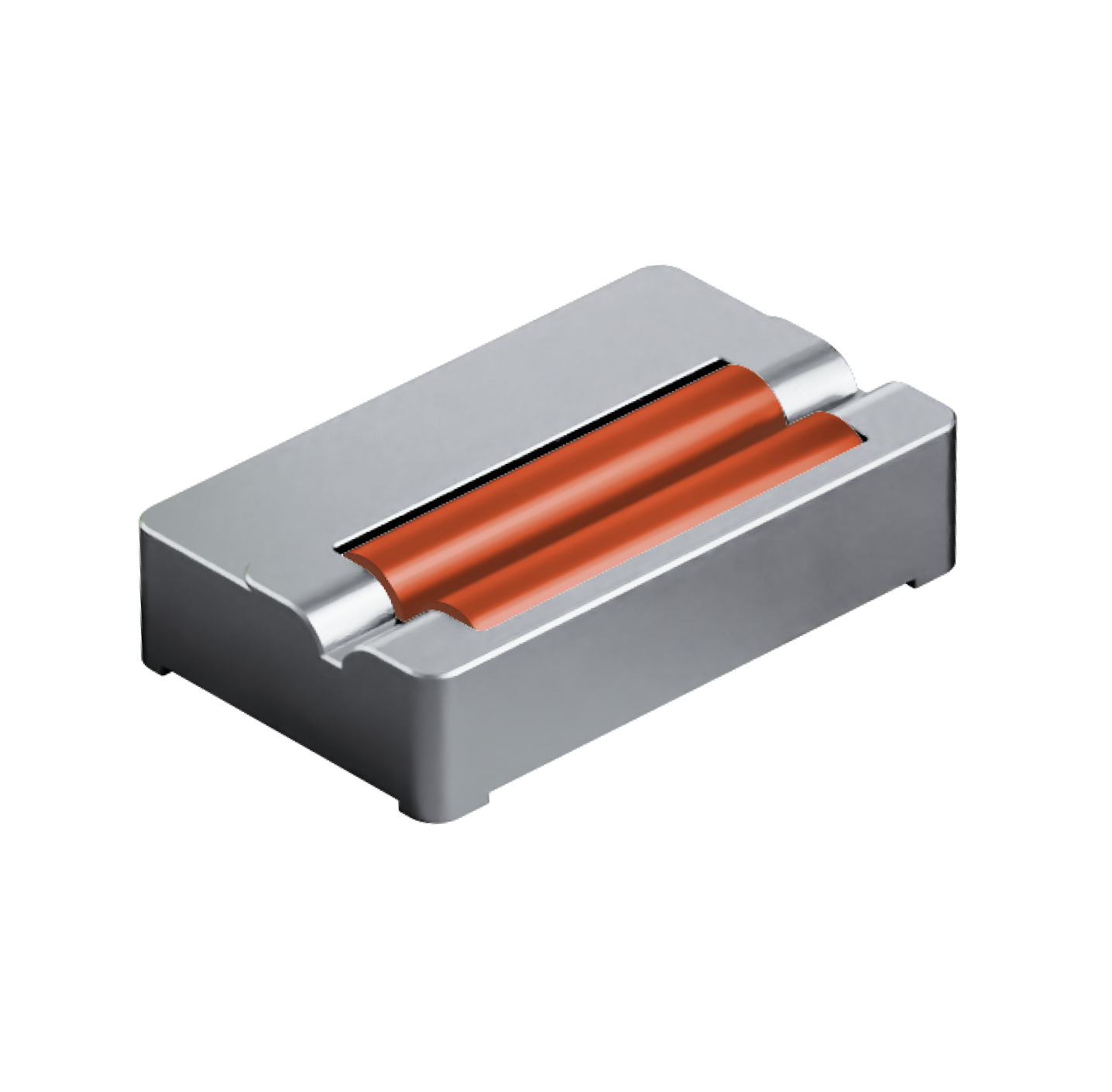

Industrial Fiber Laser. Create like a Pro Empowered by fiber laser source, the F20 excels beyond normal diode, CO2, achieving unparalleled precision, speed, and durability. It adeptly carves out complex and exquisite designs on challenging materials like metal and hard plastics. Built to last, the F20 offers a remarkable 100,000-hour lifespan with minimal upkeep, courtesy of its efficient design featuring fewer moving components.

The laser cutting machine has a power of 20W and an accuracy of 0.001mm, which is especially suitable for cutting thicker materials, such as metal, acrylic, plastic, leather, paper and other different materials. Best of all, it can reach the fastest engraving speed of 7,000 mm/s, making it a popular choice for hobbyists and businesses.

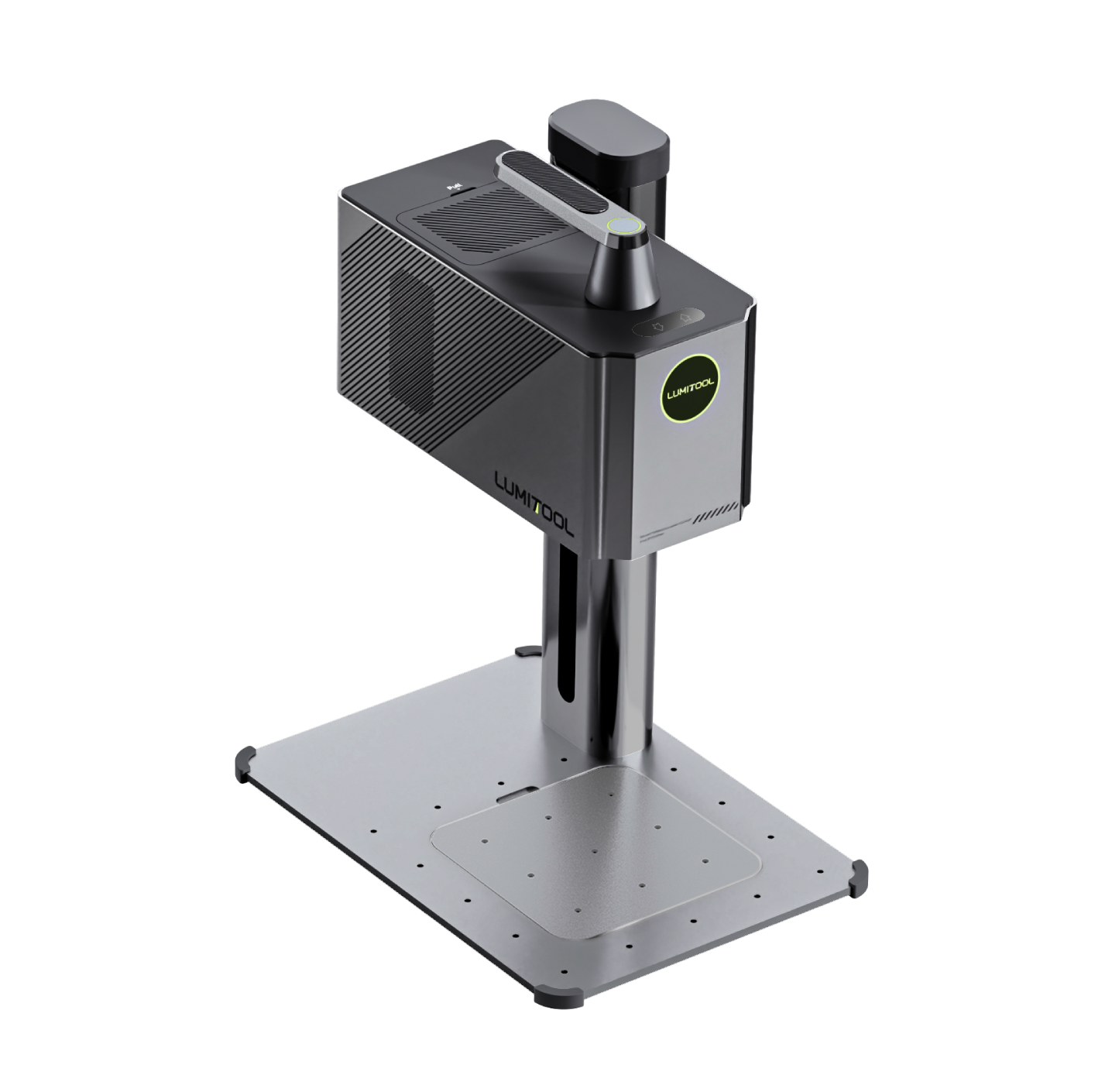

One of the outstanding features of this F20 laser cutting machine is its ability to perform rotary engraving. A rotating table in the accessory allows cylindrical objects such as glasses, wine glasses and pens to be carved with ease. Carved at any Angle of 360°, it opens up a world of possibilities for personalized gifts and promotional items. But the laser cutter's versatility doesn't end there. The machine can also support curved surface engraving.

The F20 offers impressive engraving depths of up to 1.5 mm in metal and up to 3 mm in stone. This extraordinary sculptural depth not only enhances design detail and visibility, but also injects a unique, exquisite texture into your work, making each piece an extraordinary work of art.

Work area: The LumiTool F20 offers two options for carving work area sizes :110*110mm and 175*175mm.

Overall, the Lumitool F20 is a good investment for businesses that require versatile, precise, and efficient laser cutting of various materials.

Conclusion

Laser engraving helps us cut out a wide variety of materials. We have discussed some common and non-cutting materials that can be cut with lasers, as well as the best Settings for selecting different materials. So you can confidently choose these materials for your project. We hope this article will help you choose the right material and the best setting for it.